-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

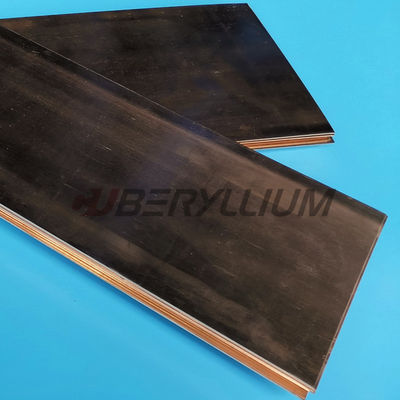

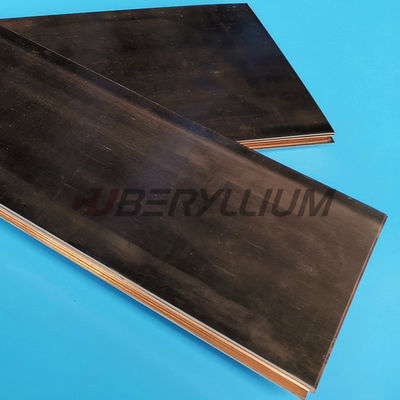

Be-Cu C17200 Plate 460 MM X 468 MM X 20 MM Polished

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Be-Cu C17200 Plates | CUBERYLLIUM® Grade | CUBERYLLIUM® 172 |

|---|---|---|---|

| Size | 460 MM X 468 MM X 20 MM | Standard | ASTM B194 |

| Safe Handling | No Special Health Risk. | Machining Property | Good |

| Surface | Bright/Polished | Flatness | Good |

| State | TF00 | Application | For Oil Process Platform |

| Highlight | Be Cu C17200 Plate,Polished C17200 Plate,Polished Beryllium Copper Sheet |

||

Be-Cu C17200 Plates Size 460 MM X 468 MM X 20 MM Polished Copper Sheet

Product Normal Description:

Product Name: C17200 plates

Standard: Be-Cu

Product Size: 460mm x 468mm x 20mm

State: TF00

Product Brand: CUBERYLLIUM®

Chemical Composition of Be-Cu C17200 Alloy:

Product Grade: CUBERYLLIUM ®-172(UNS. C17200)

| Numbering | Be | Co+Ni | Cu | Fe | Pb | Si | Al |

| C17200 | 1.8-2.0 | ≥0.2 | Margin | 0.15 | - | 0.15 | 0.15 |

Note: Copper plus additions equal 99.5% Minimum.

Standard Specificaiton For Be-Cu C17200 Plates:

| Standards | ASTM B194 |

| Grade | Alloy 25 (C17200), CDA 172 |

| Specifications | AMS 4530, AMS 4533, AMS 4534, AMS 4650, AMS 4651, SAE J461, SAE J463, JIS H 3130, RWMA Class 4 |

| Temper | A(TB00),H(TD04),AT(TF00),HT(TH04) |

Typical Physical Properties of Be-Cu C17200 Alloy:

| Density (g/cm3): | 8.36 |

| Density before age hardening (g/cm3): | 8.25 |

| Elastic Modulus (kg/mm2 (103)): | 13.4 |

| Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C): | 17 x 10-6 |

| Thermal Conductivity (cal/(cm-s-°C)): | 0.25 |

| Melting Range (°C): | 870-980 |

Temper Designations of Be-Cu C17200 Plates:

| Mechanical and Electrical Properties of C17200 Sheet/Plate | |||||||

| CUBERYLLIUM | ASTM | Heat Treatment |

Thickness (mm) |

Tensile Strength (Mpa) |

Elongation Percent |

HARDNESS Rockwell B or C Scale |

Electrical Conductivity (% IACS) |

| Designation | Designation | ||||||

| A | TB00 | All Size | 400~580 | 20~60 | B45-85 | 15~19 | |

| H | TD04 | <10 | 600~880 | 8~20 | B91-103 | 15~19 | |

| 10~25 | 600~850 | 8~20 | B90-102 | 15 ~ 19 | |||

| 25~50 | 580~820 | 8~20 | B88-102 | 15 ~19 | |||

| >50 | 580~820 | 8~20 | B88-102 | 15 ~19 | |||

| AT | TF00 | 3 hr 315℃ |

All Size | 1120~1358 | 3~10 | C36-41 | 22 ~ 28 |

| HT | TH04 | 2 hr 315℃ | <10 | 1200~1450 | 1~5 | C38-45 | 22 ~ 28 |

| 10~25 | 1200~1500 | 1~5 | C38-44 | 22 ~ 28 | |||

| 25~50 | 1200~1450 | 2~5 | C37-43 | 22 ~ 28 | |||

| >50 | 1100~1350 | 2~5 | C36-42 | 22 ~ 28 | |||

Be-Cu C17200 Plates Applications:

Beryllium Copper C17200 Plates are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a range of Be-Cu C17200 Plates for high temperature, pressure applications. These Plates is use in various industries like :

Beryllium Copper C17200 Plates uses in Power Plants

Beryllium Copper C17200 Plates uses in Modern Architecture

Beryllium Copper C17200 Plates uses in Petroleum Industry

Beryllium Copper C17200 Plates uses in General Purpose Applications

Beryllium Copper C17200 Plates uses in Fabrication Industry

Beryllium Copper C17200 Plates uses in Oil & Gas Industry

Beryllium Copper C17200 Plates uses in Fertilizers

Beryllium Copper C17200 Plates uses in Electronics

Beryllium Copper C17200 Plates uses in Construction

Beryllium Copper C17200 Plates uses in Chemical Industries

Beryllium Copper C17200 Plates uses in Plumbing

Product Photos:

![]()

Key Technology of Beryllium Copper(Heat treatment)

Age Hardening

Age hardening significantly enhances the material’s strength. This reaction is generally carried out at temperatures between 260°C and 540°C depending on alloy and desired characteristics. This cycle causes the dissolved beryllium to precipitate as a beryllium rich (gamma) phase in the matrix and at the grain boundaries. It is the formation of this precipitate which causes the large increase in material strength. The level of mechanical properties attained is determined by the temperature and time at temperature. It should be recognized that beryllium copper has no room temperature aging characteristics.