-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

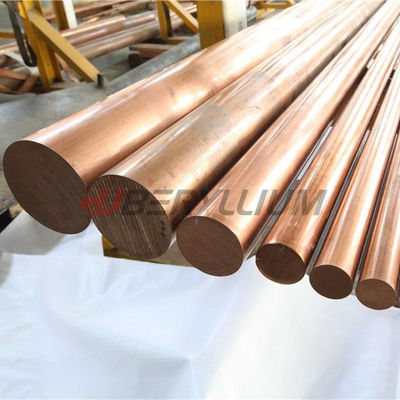

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

CuCr1Zr -UNS.C18150 Chromium Zirconium Copper Rods for Electrical Industry

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Chromium Zirconium Copper Rods | Grade | CuCr1Zr -UNS.C18150 |

|---|---|---|---|

| Item | Chromium Zirconium Copper Alloy Rods | Specification | According Customers' Requirement |

| Advantage | With High Electrical Conductivity | Safe Handling | No Special Health Risk |

| Machining Property | Good | Density G/cm³ | 8.89 |

| Cu(Min) | Standard | Export To | All Over The World |

| Highlight | c18150 copper chromium zirconium,c18150 chromium zirconium copper |

||

CuCr1Zr -UNS.C18150 Chromium Zirconium Copper Rods For Electrical Industry

Product Normal Description:

| Product Name | Chromium Zirconium Copper Rods |

|---|---|

| Grade: | CuCr1Zr, UNS.C18150 |

| Standard: | RWMA Class 2, DIN 17666 2.1293, CW106C to EN |

| Product Specification: | we could provide beryllium copper alloy according customers' requirement. |

| Delivery Time: | Usually within 10~15 days |

| Package: |

Packed in woodencases |

| Product Brand: | CUBERYLLIUM® |

UNS.C18510 chromium zirconium copper alloys is a high conductivity, high strength copper alloyed with chromium.

C18510 is heat treatable, and resists softening in service up to temperatures of 500°C. It is used for spot and seam welding electrodes, plastic mould components and other applications requiring excellent electrical and thermal conductivity and high strength and wear resistance at high temperatures. C18510 is heat treated to high strength, and requires no further heah treatment. It meets the requirements of RWMA (Resistance Welder Manufacturers Association) Group A, Class 2.

C18150 when used for spot and seam welding electrodes can provide less sticking and resists deformation longer than copper-chromium (C18200) in some specific situations. C18150 can be used instead of C18200 in any structural or current carrying application.

C18150 can be used to spot weld: cold rolled steel, hot rolled steel, nickel plated steel, zinc and zinc-aluminium coated steel (galvanised and zincalume), nickel alloys, Monel, nickel silver, stainless steel.

Chemical Composition of CuCr1Zr -UNS.C18150 Chromium Zirconium Copper Alloys:

Product Grade: CUBERYLLIUM ®-815 (UNS.C18150)

| Cr | 0.50-1.50% |

| Zr: | 0.05-0.25% |

| Cu: | Balance |

| Note: Copper plus additions equal 99.7% minimum. | |

Typical Physical Properties of CuCr1Zr -UNS.C18150 Chromium Zirconium Copper Alloys:

| Metric Units | Imperial Units | |

|---|---|---|

| Density | 8.89 gm/cm³ @ 20°C | 0.321 lb/in³ @ 68°F |

| Specific Gravity | 8.89 | 8.89 |

| Melting Point (Liquidus) | 1080°C | 1976°F |

| Melting Point (Solidus) | 1070°C | 1958°F |

| Coefficient of Thermal Expansion | 16.45 x 10 -6 / °C (20-300°C) | 9.5 x 10 -6 / °F (68-392°F) |

| Themal Conductivity | 323.9 W/m. °K @ 20°C | 187.0 BTU/ft²/ft/hr/°F @ 68°F |

| Electrical Conductivity | 0.464 MegaSiemens/cm @ 20°C | 80% IACS@ 68°F |

| Modulus of Elasticity (tension) | 117,200 MPa | 17,000ksi |

Note:

1: the units are based upon US Customary.

2: the typical physical properties apply to age hardened products.

| Typical Uses For CuCr1Zr -UNS.C18150 Chromium Zirconium Copper Alloys: | |

| Industrial: | Welding Wheels, Tips and Rod extensions for resistance seam and spot welding |

| Electrical Industry: | Resistance Welding Electrodes, Circuit Breaker Switches. |

| Consumer: | Rod Extensions, Pencil-type, Light Soldering Guns, Tip |

Product Photos:

![]()