-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

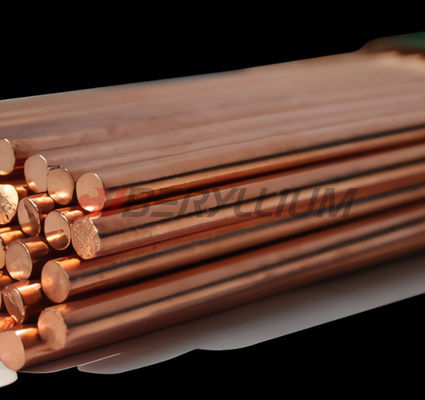

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

High Conductivity RWMA Class 2 Copper C18150 Rods

| Place of Origin | China |

|---|---|

| Brand Name | CUBERYLLIUM |

| Certification | ISO, SGS |

| Model Number | C18150 |

| Minimum Order Quantity | 50 kgs |

| Price | 20 USD |

| Packaging Details | Wooden box with PVC cover or Customers' Requirement. |

| Delivery Time | Usually 10~15 work days |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 200T/Month |

| Brand | CUBERYLLIUM | Grade | CuCr1Zr, EN CW106C, UNS C18150 |

|---|---|---|---|

| Name | C18150 Chromium Zirconium Copper Square Rods 2mm~10mm For Tips And Rod Extensions | Machining Property | Good |

| Specific Gravity | 8.89 | Shape | Round |

| Melting Point | 1070~1080℃ | Typical Uses | Resistance Welding Electrodes |

| Length | 1000mm~3000mm | Surface | Polished/Mill |

| Highlight | Rods RWMA Class 2 Copper,Copper C18150 Rods,High Conductivity RWMA Class 2 Copper |

||

RWMA Class 2 High Conducdivity Copper C18150 Rods For Resistance Welding Electrodes

Chemical Composition:

| Cr: 0.50-1.50% |

| Zr: 0.05-0.25% |

| Cu: Balance |

| Note: Copper plus additions equal 99.70% minimum. |

Common Grade Name:

|

Material No. |

EN Material No. |

EN Designation |

UNS | RWMA |

| 2.1293 | CW106C | CuCr1Zr | C18150 | Class 2 |

Typical Applications:

| Product Category | Product | Reason Category | Reason |

| Consumer | Pencil-type & Light Soldering Guns: Tips, Rod Extensions | Conductivity (Thermal) | Thermal Conductivity |

| Pencil-type & Light Soldering Guns: Tips, Rod Extensions | Mechanical Properties | Retains Strength Better Than C18200 at Elevated Temp w/ Decrease in Conduct | |

| Pencil-type & Light Soldering Guns: Tips, Rod Extensions | Mechanical Properties | Stable up to 700 F. | |

| Electrical | Resistance welding electrodes | Conductivity (Electrical) | Electrical Conductivity |

| Resistance welding electrodes | Conductivity (Thermal) | Thermal Conductivity | |

| Resistance welding electrodes | Corrosion Resistance | Oxidation Resistance | |

| Resistance welding electrodes | Mechanical Properties | High Strength | |

| Industrial | Welding Electrodes | Welding Characteristics | Weldability |

| Welding Wheels, Tips and Rod Extensions | Welding Characteristics | Weldability |

Characteristics:

CUBERYLLIUM®-815 is a high conductivity, high strength copper alloyed with chromium. C18150 is heat treatable, and resists softening in service up to temperatures of 500°C. It is used for spot and seam welding electrodes, plastic mould components and other applications requiring excellent electrical and thermal conductivity and high strength and wear resistance at high temperatures.

C18150 when used for spot and seam welding electrodes can provide less sticking and resists deformation longer than copper-chromium (C18200) in some specific situations. C18150 can be used instead of C18200 in any structural or current carrying application.

C18150 can be used to spot weld: cold rolled steel, hot rolled steel, nickel plated steel, zinc and zinc-aluminium coated steel (galvanised and zincalume), nickel alloys, Monel, nickel silver, stainless steel.

Fabrication Properties:

The most common fabrication properties of C18150 are bending, cold heading, and machining. The machinability rating of C18150 is 20. The fabrication properties of C18150 Copper can be categorized as either good, not recommended, fair, or excellent. The properties are as follows:

| Joining Technique | Suitability |

| Soldering | Good |

| Brazing | Good |

| Oxyacetylene Welding | Not Recommended |

| Gas Shielded Arc Welding | Good |

| Coated Metal Arc Welding | Not Recommended |

| Spot Weld | Not Recommended |

| Seam Weld | Not Recommended |

Available Shapes:

Forms:

Round bars, Flat bars, Square bars, Rectangular bars, Hexagon bars, Plates

Specification:

Rods/Bars/Plates/Sheets: UNS.C18150, SAE J461,463;RWMA Class 2, ISO5182-1991

European Standards: CuCr1Zr, DIN 17666 2.1293, CW106C to EN

Product Photo:

![]()

FAQ:

Q1: Do you have after-sale service?

A1: Our quality and service is our life, so even after your buying, we still offer free after sale service.

Q2. Why should I choose your products?

A2. Our products are high quality and prices are competitive.

Q3: What's your payment term?

A3: We accept TT, L/C and west union.