-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

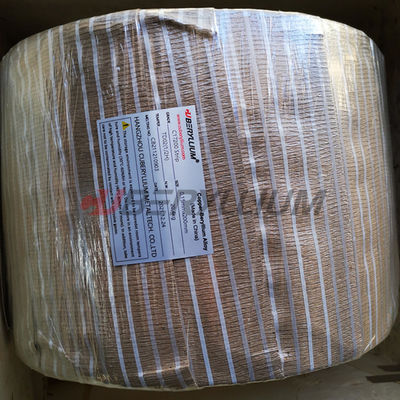

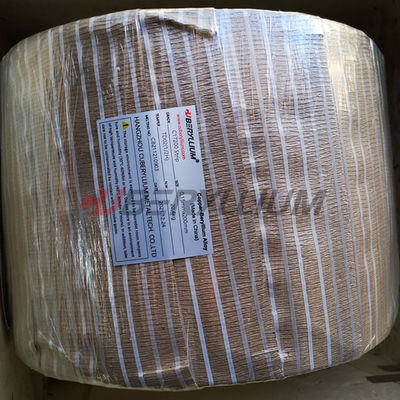

CuBe2 Beryllium Copper Strip Hardness 360 - 400HV State XHMS

| Name | CuBe2 Strip | Max Coil Wt. | 2T |

|---|---|---|---|

| Thinnest Thick. | 0.28mm | Max Width | 100mm |

| Standard | ASTM B194, SAE J463, J461 | Hardness | 360-400HV |

| Safe Handling | No Special Health Risk. | Machining Property | Good |

| Surface | Bright/Polished | Flatness | Good |

| State | XHMS | ||

| Highlight | State XHMS Beryllium Copper Strip,CuBe2 Beryllium Copper Strip,ASTM B194 Beryllium Copper Strip |

||

CuBe2 Strip On Coil 0.28mmx100mm Hardness 360~400HV(State XHMS)

Product Normal Description:

Product Name: CuBe2 Strip

Grade: CuBe2

Standard: ASTM B194, SAE J463, J461

Product Specification: 0.28mmx100mm

State: XHMS

Product Brand: CUBERYLLIUM®

Chemical Composition of CuBe2 Alloy(CUBERYLLIUM ®-172):

Beryllium(Be): 1.80-2.00%

Cobalt(Co) + Nickel(Ni): 0.20% Min

Cobalt(Co) + Nickel(Ni) + Iron(Fe): 0.60% Max

Lead: 0.02% Max

Copper(Cu): Balance

Note: Copper plus additions equal 99.5% Minimum.

| CuBe2 Strip Application: | Electrical |

|---|---|

| Fasteners | |

| Industrial | |

| Connectors, contacts | |

| Bushings/bearings for aerospace industry | |

| Oilfield drilling collars and instrument housing | |

| Springs | |

| Rugged resistance welding gun structural components | |

| Plastic injection molding and metal diecastings |

Typical Physical Properties of CuBe2 Alloy(CUBERYLLIUM ®-172):

| Density (g/cm3): | 8.36 |

| Density before age hardening (g/cm3): | 8.25 |

| Elastic Modulus (kg/mm2 (103)): | 13.4 |

| Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C): | 17 x 10-6 |

| Thermal Conductivity (cal/(cm-s-°C)): | 0.25 |

| Melting Range (°C): | 870-980 |

Temper Designations of CuBe2 Strip(CUBERYLLIUM ®-172):

| Cuberyllium Designation | ASTM | Mechanical and Electrical Properties of Copper Beryllium Strip | ||||||

| Designation | Description | Tensile Strength (Mpa) |

Yield Strength 0.2% offset | Elongation Percent | HARDNESS (HV) |

HARDNESS Rockwell B or C Scale |

Electrical Conductivity (% IACS) |

|

| A | TB00 | Solution Annealed | 410~530 | 190~380 | 35~60 | <130 | 45~78HRB | 15~19 |

| 1/2 H | TD02 | Half Hard | 580~690 | 510~660 | 12~30 | 180~220 | 88~96HRB | 15~19 |

| H | TD04 | Hard | 680~830 | 620~800 | 2~18 | 220~240 | 96~102HRB | 15~19 |

| HM | TM04 | Mill hardened |

930~1040 | 750~940 | 9~20 | 270~325 | 28~35HRC | 17~28 |

| SHM | TM05 | 1030~1110 | 860~970 | 9~18 | 295~350 | 31~37HRC | 17~28 | |

| XHM | TM06 | 1060~1210 | 930~1180 | 4~15 | 300~360 | 32~38HRC | 17~28 | |

Product Photos:

![]()

FAQ:

Q1:Could you produce Beryllium Copper strip by Mill Hardened process.

A1:Yes, we could produce AM(TM00), 1/2HM(TM01).HM(TM04) XHM(TM06) XHMS(TM08).,we are the only factory could do harden strip in China.

Q2: What’s the advantages the Beryllium Copper of CUBERYLLIUM®.

A2: 1: The Biggest Coil weight could be reach 1200kg/Coil

2:We are the only one who melting by Vacuum semi-Continuous Furnace.

3:Surface further polishing for top clients.

Q3: Why you melting by Vacuum semi-Continuous Furnace.

A3:Could be get the Cast ingot without gas,smaller segregation, Grain Refinement

Q4: What's the payment terms?

A4: We accept T/T, L/C, Paypal etc. It can be negotiated when the amount is different.