-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

UNS C17410 Beryllium Bronze Alloy Tapes For Switch Parts High Electrical Conductivity

| Product Name | UNS C17410 Beryllium Bronze Tapes | CUBERYLLIUM® Grade | CUBERYLLIUM® 741 |

|---|---|---|---|

| Max Width | 305mm | Max Coil Wt. | 2T |

| Thinest Thick. | 0.05mm | Length | 200mm, 500mm, 1000mm Or As Required |

| Standard | ASTM B768, B888 | Safe Handling | No Special Health Risk. |

| Machining Property | Good | State | 1/2 HT(TH02), HT(TH04) |

| Surface | Bright, Polished | Typical Application | For Connector Application |

| Available Shapes | Strip, Sheet | ||

| Highlight | UNS C17410 Beryllium Bronze alloy Tapes,C17410 Beryllium Bronze High Electrical Conductivity,beryllium copper tf00 C17410 |

||

High Electrical Conductivity UNS C17410 Beryllium Bronze Tapes For Switch Parts

Product Name: Beryllium Bronze Tapes

Grade: UNS C17410

Size: Thickness 0.8mm, Or as customers' requirement

State: 1/2 HT(TH02), HT(TH04)

Product Informance of CUBERYLLIUM® Company:

CUBERYLLIUM® manufactures copper beryllium in several distinct compositions. These fall into two categories: alloys selected for high strength (Alloys 172,173,170) and alloys selected for high conductivity (Alloys 751,750,741). And Gost standard QBe2,QBe1.9Ti for Russia Market. Also Supply Master alloy : CuBeryllium-200; CuBeryllium-275);CuBeryllium-350 and Cuberyllium-400 to global factory.

CUBERYLLIUM ®-741 also named -C17410 Copper alloy with low beryllium content. Alloy C17410 Copper Beryllium Strip is a mill hardened alloy designed for use in the automotive, applicance and telecommunication markets.

If provides high yield and fatigue strength with high electrical conductivity and good resistance to stress relaxation.

Chemical Composition of UNS C17410 Beryllium Bronze Alloys:

| Elements | ||||||

|---|---|---|---|---|---|---|

| Cu | Fe | Al | Be | Co | Si | |

| Min (%) | 0.15 | 0.35 | ||||

| Max (%) | Rem | 0.2 | 0.2 | 0.50 | 0.60 | 0.2 |

| (1) Cu + Sum of Named Elements 99.5% Min. | ||||||

| (2) Cu value includes Ag. | ||||||

Forms Available

Alloy 174 mill hardened strip is available in widths ranging from 1mm~300mm and in thicknesses ranging from 0.02 to 2.5mm.

Typical application of UNS C17410 Beryllium Bronze Tapes:

Bearings

Plastic molds

Welding electrodes

Current-carrying springs

Corrosioin resistant components

Precision screw machined parts

Connectors for appliances and consumer electronics

| Related material specifications of UNS C17410 Beryllium Bronze Alloys | |

| Strips | ASTM B768, B888 |

| Sheets | ASTM B768, B888 |

Typical Physical Properties of UNS C17410 Beryllium Bronze Alloys:

| Elastic Modulus | Melting Point (Solidus) | Electrical Conductivity/ Resistivity |

Density |

Thermal Expansion Coefficient | Thermal Conductivity (25 °C) |

| 138 GPa | 1020 °C | 2.9-3.8 μΩcm | 8.80 g/cm3 | 17.6 x 10-6 m/m °C | 230 W/ m K |

MECHANICAL PROPERTIES of UNS C17410 Beryllium Bronze Tapes:

| 0.2% Offset Yield Strength (min) | Ultimate Tensile Strength (min) | Elongation (min) | ||||

| Temper | Hardness | |||||

| ksi | MPa | ksi | MPa | % | HV | |

|

1/2HT(TH02) |

80 - 100 | 550 - 690 | 95 - 115 | 665 - 790 | 10~20 | 180 - 230 |

| HT(TH04) | 100 - 120 | 690 - 830 | 110 - 130 | 760 - 895 | 7~17 | 210 - 278 |

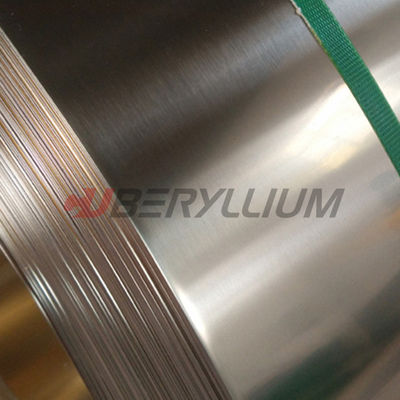

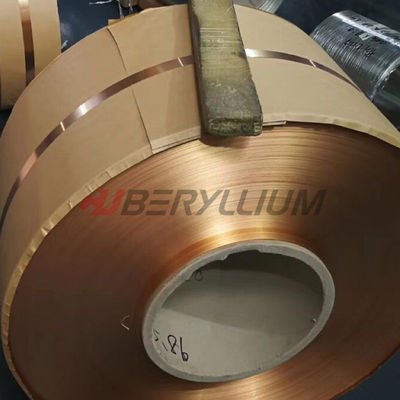

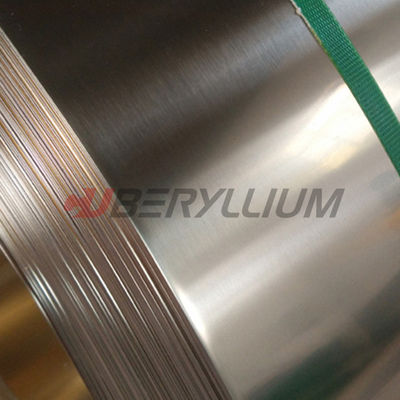

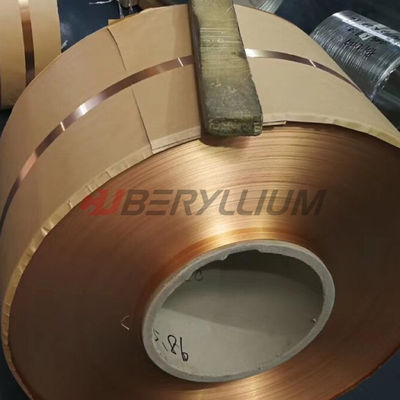

Product Photo:

![]()

Health and Safety

Processing beryllium-containing alloys poses a health risk if safe practices are not followed. Inhalation of airborne beryllium can cause serious lung diseases in some individuals. Occupational safety and health regulatory agencies worldwide have set mandatory limits on occupational respiratory exposures. Read and follow the guidance in the Safety Data Sheet (SDS) before working with this material.

For questions on safe practices for beryllium-containing alloys, contact us by e mail at info@cuberyllium.com

FAQ:

Q1:Could you produce Beryllium Copper strip by Mill Hardened process.

A1:Yes, we could produce AM(TM00), 1/2HM(TM01).HM(TM04) XHM(TM06) XHMS(TM08).,we are the only factory could do mill harden strip in China.

Q2: What’s the advantages the Beryllium Copper of CUBERYLLIUM®.

A2: 1: The Biggest Coil weight could be reach 1200kg/Coil

2:We are the only one who melting by Vacuum semi-Continuous Furnace.

3:Surface further polishing for top clients.

Q3: Why you melting by Vacuum semi-Continuous Furnace.

A3:Could be get the Cast ingot without gas,smaller segregation, Grain Refinement

Q4: What's the payment terms?

A4: We accept T/T, L/C, Paypal etc. It can be negotiated when the amount is different.