-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

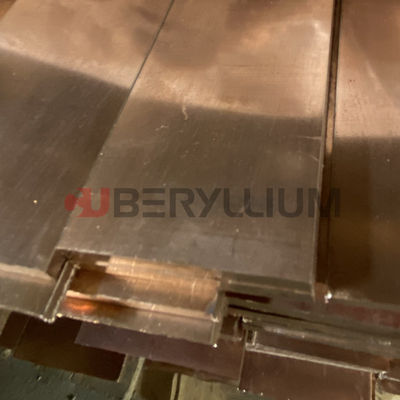

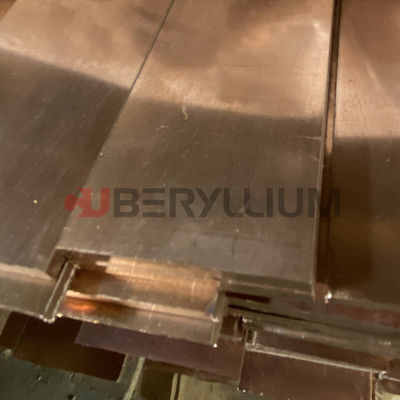

CW101C Be Cu Bronze Sheet Beryllium Based Metals 10mm 20mm 30mm

| Name | CW101C Be-Cu Bronze Sheet | CUBERYLLIUM® Grade | CUBERYLLIUM® 172 |

|---|---|---|---|

| Thickness | Customized | Standard | ASTM B194 |

| Safe Handling | No Special Health Risk. | Machining Property | Good |

| Surface | Bright/Polished | Flatness | Good |

| State | TF00 | Application | For Oil Process Platform |

| Highlight | CW101C Be Cu Bronze Sheet,10mm Bronze Sheet,30mm Bronze Sheet |

||

CW101C Be-Cu Bronze Sheet Beryllium-based Metals Sheet 10mm 20mm 30mm

| Usage/Application | Industrial |

| Alloy | With Alloy |

| Pack Type | Sheet, Plate |

| Grade | CW101C, C17200, CuBe2, CDA 172 |

| Storage Temperature | 0-25 degree C |

| Thickness | 10-200mm |

| Cu Content | Rem. |

| Customisation | Customised |

About CW101C Be-Cu Bronze Alloy:

Copper Beryllium Alloys are precipitation hardening alloys possessing remarkable strength, elasticity and fatigue resistance and good resistance to corrosion. This makes them ideal for a number of demanding industry sectors such as Petrochemical, Oil and Gas and Mining. The fatigue and elasticity of Beryllium Copper are useful in pressure responsive components such as spring applications. It is also increasingly machined into miniaturised components, required by Electronics and Telecommunication manufacturing for everyday items such as mobiles, laptops and tablets. The principal compositions consist of around 1.6% to 2.0% Beryllium, with a small addition of Cobalt to refine grain size. We can supply these alloys can in the following forms:

i) Solution treated (Annealed), or

ii) Solution treated & temper rolled, i.e. 1/4 Hard, 1/2 Hard, Hard, etc.

Properties of CW101C Be-Cu Bronze Alloy:

Fast Heating & Fast Cooling

Excellent Conductivity

High Tensile Strength

Non Oxidizing Acid Resistance

Wear & Gall Resistant

Non Sparkling

High Fatigue Resistance

Elevated Temperature Strength

Corrosion Resistance

Ductile, Weldable & Machinable

High Melting Point

Dimension Stability

| Chemical composition % by Weight of CW101C Be-Cu Bronze Alloy | |||

| Be | Ni + Co | Ni+Co+Fe | Cu |

| 1.80 - 2.00 | .02 min. | .06max. | Balance |

Typical Physical Properties of CW101C Be-Cu Bronze Alloy:

| Density | Specific Heat | Electrical Conductivity (I.A.C.S) | Thermal Conductivity |

| 8.36g/cm³ | 0.42 J/g.K | Min. 24% | 106 W/m.K |

Product Photos:

![]()

FAQ:

- How can I identify high-quality copper alloy products?

By the physical shape, the proper analysis, and the correct mechanical values.

- Is there a possibility to order customized copper alloys?

Different copper alloys are tested for a very long time and always applicable to individual demands.

We have the experience to help customers producing customized products as per the customers' drawings.

- What is the delivery time of copper alloys from Cuberyllium?

Usually with 7-10 working days, it will depend on the final qty requested by customers.

- What are the benefits of using Copper Alloys?

Copper Alloys offer many manufacturing benefits including strength, conductivity, corrosion resistance, machinability and ductility. With superior electrical and thermal conductivity, and an attractive appearance, Copper Alloys are suitable for a wide range of applications.

- What are the disadvantages of using Copper Alloys?

Copper Alloys can be more susceptible to corrosion, particularly oxidation. which can impact it suitability for some applications.