-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

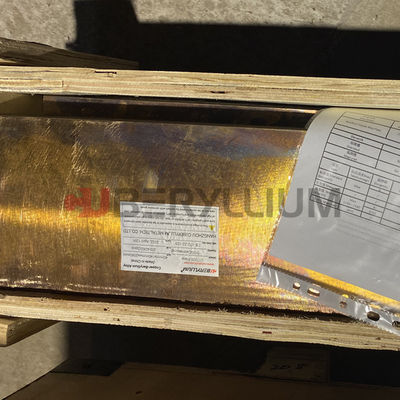

Rwma Beryllium Copper Plates 265x260x2110mm CuBe2 Square

| Name | CuBe2 Square Plates | CUBERYLLIUM® Grade | CUBERYLLIUM® 172 |

|---|---|---|---|

| Thickness | Customized | Standard | ASTM B194 |

| Safe Handling | No Special Health Risk. | Machining Property | Good |

| Surface | Bright/Polished | Flatness | Good |

| State | TF00 | Application | For Industry Application |

| Highlight | Rwma Beryllium Copper Plates,CuBe2 Square Plates,Square Beryllium Copper Plates |

||

Rwma Beryllium Copper Plates 265*260*2110mm CuBe2 Square Plates

Rwma Beryllium Copper Plates 265*260*2110mm CuBe2 Square Plates

| Usage/Application | Industrial |

| Alloy | With Alloy |

| Pack Type | Sheet, Plate, Square Plate |

| Grade | CW101C, C17200, CuBe2, CDA 172 |

| Storage Temperature | 0-25 degree C |

| Plate Size | 265*260*2110mm |

| Cu Content | Rem. |

| Customisation | Customised |

Introduction Rwma Beryllium Copper Alloy/CuBe2 Copper Alloy:

RWMA Class 4, BERYLLIUM-COPPER has extremely high hardness, and is recommended for projection, flash and butt-welding dies. It has lower conductivity than Class 3 alloy but it is harder and more wear resistant. It should be considered where there is concern with high-pressure density and severe wear, but where heating, due to its low conductivity, is no excessive.

It is used frequently in the form of inserts, die facings, and seam welder bushings. It is available in the annealed condition, which is more readily machined, and then subsequently heat-treated.

Also Known as CuBe2, UNS. C17200.

| Chemical Composition and Typical Physical properties of Beryllium Copper Alloy/CuBe2 Copper Alloy | ||

| Chemical Composition | ||

| Be | 1.8-2.0 | |

| Ni+Co(Min.) | 0.02 | |

| Ni+Co+Fe(Max.) | 0.06 | |

| Cu | Rem. | |

| Typical Physical properties | ||

| Thermal Conductivity | BTU/(ft hr F) | 60 |

| Specific Heat | BTU/lb/ F | 0.1 |

| Thermal Expansion | in/in/F | 9.7 x 10 -6 |

| Density | lb/cu in | 0.298 |

| Hot Forming | 1350-1500 ℉ | Air or Water Cooled |

| Heat Treatment | Anneal 1425-1475 ℉ in apporx.HB 150 Hardened 600 ℉ to approx. HB 370 |

1/2 hr. & Water Quench 3 hr. Air Cool |

| Class IV beryllium copper is pre-tempered to the correct strength. Hot forming and further heat treatment are not needed or recommended. Direct machining to desired confituration is preferred. | ||

Most Commonly Temper Used for Beryllium Copper Alloy/CuBe2 Copper Alloy:

C17200 Beryllium Copper Alloys Rods/Bars/Tubes: A(TB00),H(TD04),AT(TF00),HT(TH04)

C17200 Beryllium Copper Alloys Strips: A(TB00),1/4 H(TD01),1/2 H(TD02),H(TD04)

C17200 Beryllium Copper Alloys Sheets: A(TB00),1/4 H(TD01),1/2 H(TD02),H(TD04),AT(TF00)

C17200 Beryllium Copper Alloys Wires: A(TB00),1/4 H(TD01),1/2 H(TD02),3/4H(TD03),H(TD04)

C17200 Beryllium Copper Alloys Plates: A(TB00),H(TD04),AT(TF00),HT(TH04)

Heat Treated Tempers

These tempers describe the resulting strength after optimum heat treatment of their age hardenable counter parts.

ASTM Designation Description Name

TF00 Annealed & Heat Treated AT

TH01 Quarter Hard & Heat Treated 1/4 HT

TH02 Half Hard & Heat Treated 1/2 HT

TH04 Hard & Heat Treated HT

Physical Property of Beryllium Copper Alloy/CuBe2 Copper Alloy:

High strength

High hardness

High elasticity

Superior fatigue resistance

Superior abrasion resistance

Superior mouldability and isotropy

Product Photos:

![]()

![]()

More Products Cuberyllium could provide:

More range of copper and copper alloys, in full series of shapes: Sheet, Bar, Tubes, Strips and Wire list as below:

C17000/170 (CuBe1.7, 2.1245, Alloy165)

C17200/172 (CuBe2, 2.1247, Alloy25)

C17300/173 (CuBe2Pb, 2.1248, AlloyM25)

C17500/175 (CuCo2Be, 2.1285, Alloy10)

C17510/1751 (CuNi2Be, 2.0850, Alloy3)