-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

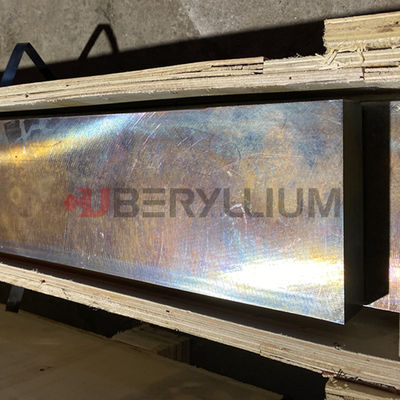

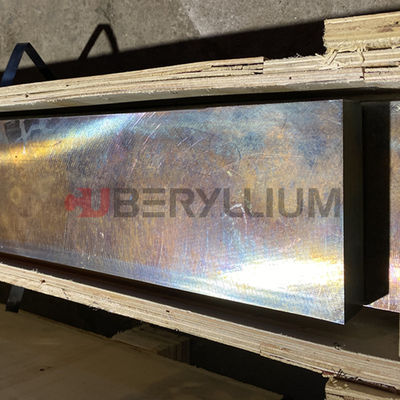

C71200 Beryllium Copper Plate Thin Sheet Polished

| Name | C71200 BERYLLIUM COPPER PLATE | CUBERYLLIUM® Grade | CUBERYLLIUM® 172 |

|---|---|---|---|

| Thickness | 10mm | Standard | ASTM B194 |

| Safe Handling | No Special Health Risk. | Machining Property | Good |

| Surface | Bright/Polished | Flatness | Good |

| State | TF00 | Application | For Oil Process Platform |

| Highlight | Thin C17200 Beryllium Copper Sheet,Polished C17200 Beryllium Copper Plate,C17200 Bronze Sheet Plate |

||

C71200 BERYLLIUM COPPER PLATE Copper Thin Sheet Bronze Sheet Plate

| Normal Production Description | |

| Name | C17200 Beryllium Copper Plate |

| Product Type | Thin Sheet |

| Thickness | 10mm THX |

| Temper | TF00, Aging Heat Treatment |

| Application | For industrial |

| Material | Copoer Alloy, Bronze Alloy |

About CUBERYLLIUM ®:

Cuberyllium is a factory specialized on Bronze Alloy Products for more than 20 years.

Cuberyllium has Casting, Die Forging, Extrusion and Heat Treatment within our plants. The products manufactured have many critical applications from autmotive to marine industry, from electrical industry to aviation.

Beryllium Copper Alloy Introduction

One of the highest strength copper based alloys available on the market today is beryllium copper, also known as spring copper or beryllium bronze. The commercial grades of beryllium copper contain 0.4 to 2.0 percent beryllium. The small ratio of beryllium to copper creates a family of high copper alloys with strength as high as alloy steel. The first of the two families, C17200 and C17300, includes high strength with moderate conductivity, while the second family, C17500 and C17510, offers high conductivity with moderate strength. The principle characteristics of these alloys are their excellent response to precipitation-hardening treatments, excellent thermal conductivity, and resistance to stress relaxation.

Typical Applications of C71200 BERYLLIUM COPPER ALLOY:

Applications(C17200)

Non-sparking and Non-Magnetic Tools

Hard-Wearing Parts

Bushings for Landing Gear

Bushings and Liners for Oil&Gas Industry

Die-Casting Plunger Tips

Molds for Plastic Injection and Low Gravity Die-Casting

Drilling Technology

Downhole Applications in Oil Industry

Chilling for Casting Molds

| Chemical Composition of C17200 Beryllium Copper | |||

| Cu/ Copper | Be/ Beryllium | Ni + Co/ Nickel + Cobalt | Ni + Co +Fe/ Nickel +Cobalt + Iron |

| % rem | % 1.8-2.0 | 0.2% Min. | 0.6% Max. |

Typical Physical Properties of C17200 Beryllium Copper:

| Mechanical Properties | C17200 | |||

| Hardness | Brinell | 255-297 | RC 25-32 | |

| Tensile Strength | KSI | 130 | ||

| Yield Strength | KSI | 110 | ||

| Elongation | % | 7 | ||

| Elastic Modules | KSI | 18500 |

Product Photos:

![]()

Why choose Cuberyllium Metal for beryllium copper alloy products?

1,We could offer a wide selection of Beryllium Copper Alloys.

2,Broad range of products and custom capabilities

3,Modern, state-of-the-art facilities and equipment

4,Beryllium Copper Alloys in Wholesale Price

5,Shipping Beryllium Copper Alloys worldwide & fast delivery

| TEMPER DESIGNATIONS |

| Wrought Products |

| A (TBOO) Solution annealed. Softest temper. |

| H (TD04) Solution annealed and fully cold-worked. |

| AT (TF00) Precipitation hardened A temper. |

| HT (TH04) Precipitation hardened H temper. Hardest temper. |

Standards of Beryllium Copper Alloy Grade:

| RWMA CLASS | RWMA NUMBER | DESCRIPTION |

| 3 | 17500 | Cobalt -Beryllium Copper |

| 3 | 17510 | Nickel-Beryllium Copper |

| 4 | 17200 | Beryllium Copper |