-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

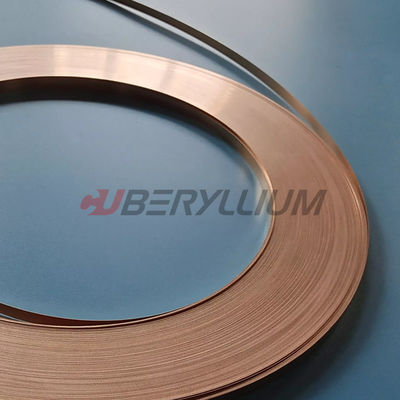

CuBe2 Tape On The Reel Dimensions Thcikness 0.25mm Width 15mm

| Name | CuBe2 Tape | Max Coil Wt. | 2T |

|---|---|---|---|

| Thinnest Thick. | 0.25mm | Width | 15mm |

| Standard | ASTM B194, SAE J463, J461 | Hardness | 260~310HV |

| Safe Handling | No Special Health Risk. | Machining Property | Good |

| Surface | Bright/Polished | Flatness | Good |

| Temper | 1/2H | ||

| Highlight | CuBe2 Beryllium Copper Tape,Width 15mmBeryllium Copper Tape,Tape C17200 Beryllium Copper |

||

CuBe2 Tape On The Reel Dimensions Thcikness 0,25mm x Width 15mm

Product Normal Description:

| Product Name | Beryllium copper tape |

| Grade | CuBe2 |

| End Product Form | Strips/Tape |

| Standard | ASTM B194 |

| State of product | 1/2H |

| Specification |

Thickness: 0.25mm Width: 15mm |

| Application | Battery socket for automobile |

Chemical Composition of CuBe2 Copper Alloy:

| Numbering | Be | Co+Ni | Cu | Fe | Pb | Si | Al |

| C17200 | 1.8-2.0 | ≥0.2 | Margin | 0.15 | - | 0.15 | 0.15 |

Temper Designations of CuBe2 Tape:

| Cuberyllium Designation | ASTM | Mechanical and Electrical Properties of CuBe2 Tape | ||||||

| Designation | Description | Tensile Strength (Mpa) |

Yield Strength 0.2% offset | Elongation Percent | HARDNESS (HV) |

HARDNESS Rockwell B or C Scale |

Electrical Conductivity (% IACS) |

|

| A | TB00 | Solution Annealed | 410~530 | 190~380 | 35~60 | <130 | 45~78HRB | 15~19 |

| 1/2 H | TD02 | Half Hard | 580~690 | 510~660 | 12~30 | 180~220 | 88~96HRB | 15~19 |

| H | TD04 | Hard | 680~830 | 620~800 | 2~18 | 220~240 | 96~102HRB | 15~19 |

| HM | TM04 | Mill hardened |

930~1040 | 750~940 | 9~20 | 270~325 | 28~35HRC | 17~28 |

| SHM | TM05 | 1030~1110 | 860~970 | 9~18 | 295~350 | 31~37HRC | 17~28 | |

| XHM | TM06 | 1060~1210 | 930~1180 | 4~15 | 300~360 | 32~38HRC | 17~28 | |

What are the Properties of Beryllium Copper?

Properties of BeCu:

Beryllium copper is a ductile, machinable, and weldable alloy.

BeCu has an excellent response to precipitation-hardening treatments.

BeCu has excellent thermal conductivity (62 Btu/ft-deg.F-H), and it is about 3-5 times more conducting than Tool steel.

It shows resistance to stress relaxation.

It is resistant to non-oxidizing acids such as hydrochloric acid (HCl) and carbonic acid (H2CO3), to plastic decomposition products, to abrasive wear, and galling.

It can be heat-treated for increased strength, durability, and electrical conductivity.

Beryllium copper displays the maximum strength (up to 1,400 MPa (200,000 psi)) of any copper-based alloy.

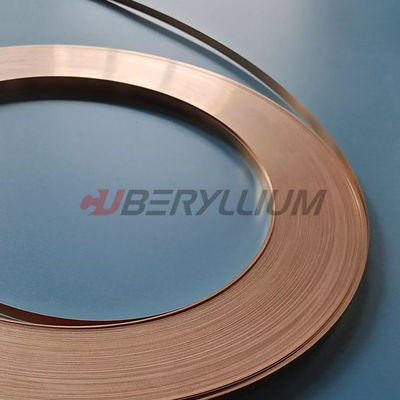

Product Photo of CuBe2 Tape:

![]()

Excellent Properties of CuBe2 Copper Alloys:

![]()

Key Technology of Beryllium Copper(Heat treatment)

Age Hardening

Age hardening significantly enhances the material’s strength. This reaction is generally carried out at temperatures between 260°C and 540°C depending on alloy and desired characteristics. This cycle causes the dissolved beryllium to precipitate as a beryllium rich (gamma) phase in the matrix and at the grain boundaries. It is the formation of this precipitate which causes the large increase in material strength. The level of mechanical properties attained is determined by the temperature and time at temperature. It should be recognized that beryllium copper has no room temperature aging characteristics.