-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

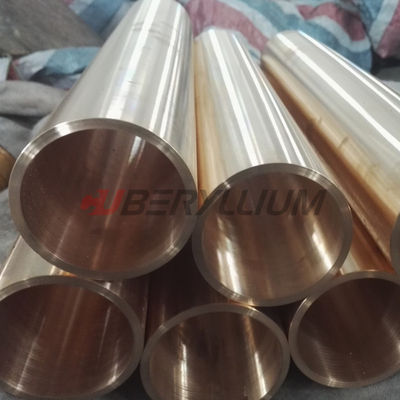

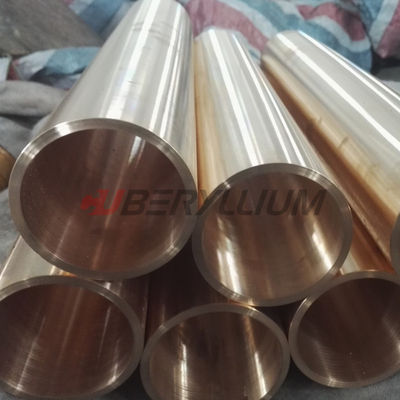

TD04 TB00 C17510 Nickel Beryllium Copper Pipe High Conductivity For Spring Connectors

| Name | Nickel Beryllium Copper Tube | Grade | UNS. C17510 |

|---|---|---|---|

| ASTM | ASTM B 937, SAE J 461, SAE J 463, RWMA Class 3, EN 12163, EN 12165, EN 12167 | Temper | A(TB00), H(TD04), AT(TF00), HT(TH04) |

| Surface | Bright | Typical Application | Electrical Industry, Fasteners, Industrial |

| Shape For Available | Round Tube, Hollow Bars, Pipes | Size | All Size |

| Brand | CUBERYLLIUM® | Type | Straight Copper Tube |

| Highlight | TD04 C17510 Nickel Beryllium Copper Pipe,TD04 TB00 C17510 Nickel Beryllium Copper Pipe,TD04 C17510 beryllium aluminum Tube |

||

Nickel Beryllium Copper Pipe UNS. C17510 With High Conductivity For Spring Connectors

Product Description:

Name: Nickel Beryllium Copper Pipe

Grade: UNS. C17510 (CUBERYLLIUM® 751)

End Product Form: Pipe, Tube

State: A(TB00), H(TD04), AT(TF00), HT(TH04)

Standard: ASTM B 937, SAE J 461, SAE J 463, RWMA Class 3, EN 12163, EN 12165, EN 12167

Application: Used for spring connectors

Feature: with highly conductivity

Package: in plywoode cases or wooden cases

Size: Custom Diameter & Sizes, Random Mill Lengths

Application Introduction of Nickel Beryllium Copper Alloy:

The most common uses for 17510 are in those applications that need a lot of conductivity of temperature or electricity. Its ultimate tensile strength is 140 ksi while its hardness is RB 100. The conductivity of C17510 is about 45-60% of regular copper.

| Feature | Application |

| C17510 has high strength. | It is recommended for highly stressed welder structural current carrying members and heavy duty offset electrode holders, such as projection welding dies, flash and butt welding dies, current carrying shafts, and bushings. |

| C17510 has high electrical resistance, it is heat treatable. | It is generally recommended for spot welding and seam welding steels, such as stainless steel. |

Chemical Composition of Nickel Beryllium Copper Alloy UNS. C17510:

| CUBERYLLIUM® Brand | UNS-Number | Beryllium | Nickel | Copper |

| Cuberyllium-C751 | C17510 | 0.20~0.60 | 1.4~2.2 | Balance |

Related material specifications of Nickel Beryllium Copper Alloy UNS. C17510:

Tubes/Pipes: ASTM B 937, SAE J 461, SAE J 463, RWMA Class 3, EN 12163, EN 12165, EN 12167

European Standards: CuNi2Be, CuNiBe, Alloy 3, DIN. 2.0850, CW110C to EN

Note:

ASTM: American Society for Testing and Materials

SAE: Society of Automotive Engineers

AMS: Aerospace Materials Specification(Published by SEA)

RWMA: Resistance Welder Manufacturers' Association

Note: Unless otherwise specified, material will be produced by ASTM.

Typical Physical Properties of Nickel Beryllium Copper Alloy UNS. C17510:

| Density | 8.83 | g/cm3 |

| Density before age hardening | 8.75 | g/cm3 |

| Elastic Modulus | 14.1 | kg/mm2 (103) |

| Thermal Expansion Coefficient | 18x10-6 | 20 °C to 200 °C m/m/°C |

| Thermal Conductivity | 0.57 | cal/(cm-s-°C) |

| Melting Range | 1000-1070 | °C |

Temper Designations of Nickel Beryllium Copper Pipe UNS. C17510 (CUBERYLLIUM ®-751):

| Cuberyllium Designation | ASTM | Mechanical and Electrical Properties of Copper Beryllium Tube/Pipe | |||||

| Temper |

Outside Diameter or Distance Between Parallel Surfaces (mm) |

Tensile Strength (Mpa) |

Yield Strength 0.2% offset(Mpa) | Elongation Percent | HARDNESS (Rockwell B Scale) |

Electrical Conductiviry percent(IACS) | |

| A | TB00 | All sizes | 240~380 | 70~210 | 20-35 | B20-50 | 20-30 |

| H | TD04 | up to 76 | 440~550 | 340~520 | 10-15 | B60-80 | 20-30 |

| AT |

TF00 | All sizes | 680~890 | 550~690 | 10-25 | B92-100 | 45-60 |

| HT | TH04 | up to 76 | 750 ~ 960 | 650 ~ 860 | 5-25 | B95-102 | 48-60 |

Product Photo:

![]()

FAQ:

Q1:What’s the advantages the Beryllium Copper of CUBERYLLIUM®?

A1: 1: The Biggest Coil weight could be reach 1200kg/Coil

2:We are the only one who melting by Vacuum semi-Continuous Furnace.

3:Surface further polishing for top clients.

Q2: How about your payment terms?

A2: Generally, 30% as deposit by T/T, then 70% should be paid before the delivery.

Q3: Why you melting by Vacuum semi-Continuous Furnace?

A3:Could be get the Cast ingot without gas,smaller segregation, Grain Refinement

Q4: What's the payment terms?

A4: We accept T/T, L/C, Paypal etc. It can be negotiated when the amount is different.