-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

C17300 Beryllium Copper Rod Alloy 2mm - 8mm For Automotive DIN2.1248

| Place of Origin | China |

|---|---|

| Brand Name | CUBERYLLIUM |

| Certification | ISO ROHS |

| Model Number | C17300 |

| Minimum Order Quantity | 30kg |

| Price | USD 30~50/KG |

| Packaging Details | Packed with waterproof paper or woven bag, then put it into wooden box or pallets. |

| Delivery Time | 10~15 working days |

| Payment Terms | L/C, T/T, MoneyGram |

| Supply Ability | 50T/Month |

| Name | DIN2.1248 Beryllium Copper Alloy Rod C17300 2mm-8mm For Automotive Manufacturing | Grade | C17300 |

|---|---|---|---|

| Standard | AMS 4650,4651,4533,4534 | Machining Property | Good |

| Diameter | 2mm~8mm | Typical Application | Automotive Manufacturing |

| Shape For Available | Round,Rectangle | Surface | Bright,Polished |

| State | A(TB00), H(TD04), AT(TF00) | Length | 3000mm |

| Density | 8.36g/cm3 | Safe Handling | No Special Health Risk. |

| Highlight | 8mm C17300 Beryllium Copper Rod,2mm C17300 Beryllium Copper Rod,Automotive C17300 Beryllium Copper Rod |

||

DIN2.1248 Beryllium Copper Alloy Rod C17300 2mm-8mm For Automotive Manufacturing

Product Specification:

|

Name |

DIN2.1248 Beryllium Copper Alloy Rod C17300 2mm-8mm For Automotive Manufacturing |

|

Standard |

ASTM B194,B196 |

|

|

AMS 4650,4651,4533,4534 |

|

|

MILITARY MIL-C-21657 |

|

|

SAE J463,J461 |

|

Diameter |

1mm~30mm |

|

Length |

1000mm-6000mm or as required |

|

Export to |

Indonesia,Ukraine,USA,Brazil,Thailand,VietNam,Korea,lndia, Egypt.Dubai,Kuwait,Malaysia,Russia,Australia,etc |

|

Package |

Packed with waterproof paper or woven bag, then put it into wooden box or pallets. |

|

MOQ |

30Kg |

|

Application |

Copper bar can be made as all kindsof deeping drawing and bending str-ess components,Such as pin, rivetswashers, nuts, ducts, air gauge, screenmesh, radiator parts, etc. |

|

|

Parts with medium strength and high conductivity, such as fuse links, springs, connectors, resistance spot welding heads, seam welding rollers, die casting machines, plastic molding molds, etc |

|

|

Electrical Industry: Switch Parts, Relay parts, Electrical Connectors, Fuse Clips, Contact Bridges, Electrical Motor Components, Navigational Instruments, Electrical Switch and Relay Blades. |

Advantages:

1. The surface of the product is smooth and flat without rust, scratch, delamination, pinhole and bubble.

2. We have professional production equipment and use vacuum Semi- Continuous Furnace for melting, which can obtain the Cast ingot without gas,smaller segregation, Grain Refinement.

3. Various Types of Specifications. Multiple specifications optional, support customized.

Detailed Specifications:

| Bar/Rod | Diameter:1.0-200mm Length:1000-6000mm |

| Sheet/Plate | Thickness:0.2-100mm Width:100-1000mm Length:1000-2000mm |

| Strip/Tape | Thickness:0.01-2.0mm Width:4-1000mm |

| Pipe/Tube | Thickness:0.1-100mm OD:1-600mm |

Lead Time:

| Quantity(kilograms) | 1 - 50 | 51 - 100 | >100 |

| Est. Time(days) | 7 | 15 | To be negotiated |

Service:

1) Timely Delivery: All inventory products can be delivered in time.

2) Customer service replied in a timely manner, and problems were solved in time.

Mechanical and Electrical Properties:

| Temper(*) | Diameter | Heat Treatment | Tensile Strength ksi |

Elogation Percent (Min) |

Electrical Conductivity Percent IACS |

Hardness Rockwell B or C Scale |

|---|---|---|---|---|---|---|

| A(TB00) | ALL SIZE | / | 400~600 | 30 | 15~19 | B45~85 |

H(TD04) |

5~10 | / | 660~900 | 5 | 15~19 | >B88 |

| >10~25 | / | 620~860 | 5 | 15~19 | ||

| >25 | / | 590~830 | 5 | 15~19 | ||

| AT(TF00) | ALL SIZE | 3 hr 320°C | 1100~1380 | 2 | 22~28 | C35~42 |

| HT(TH04) | 5~10 | 2 hr 320°C | 1200~1550 | 1 | 22~28 | C37~45 |

| >10~25 | 1150~1520 | 1 | 22~28 | C36~44 | ||

| >25 | 1120~1480 | 1 | 22~28 | C35~44 |

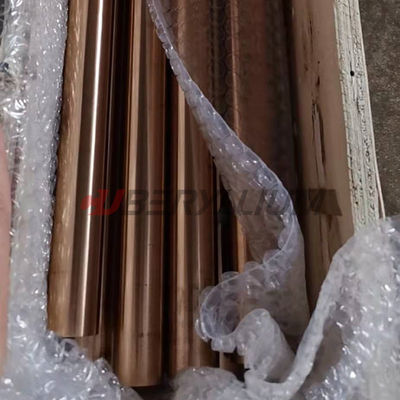

Product Photos:

![]()

Alloy M25 can be supplied in the form of bar or wire based on different design needs. Also there are different supply states for customers to choose according to different needs. C17300 also has good welding performance, wear resistance and adhesion resistance. It can be forged into parts of various shapes. Beryllium copper c17300 has better strength and wear resistance than chromium zirconium copper alloy.

FAQ:

1. How can I contact with your company?

We are always ready to serve you via Email, Telephone, Fax, Whatsapp or Mobile telephone.

Mobile/Wechat/Whatsapp: +86-17376550856

Email:info@cuberyllium.com

2. What is the lead time?

Usually 7 days after payment has been confirmed.

3. What is your payment terms?

T/T,L/C,Western Union,MoneyGram,Paypal.

4. What’s your advantage?

1) Professional production equipment.

2)Smooth surface.

3) Complete specification.