-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

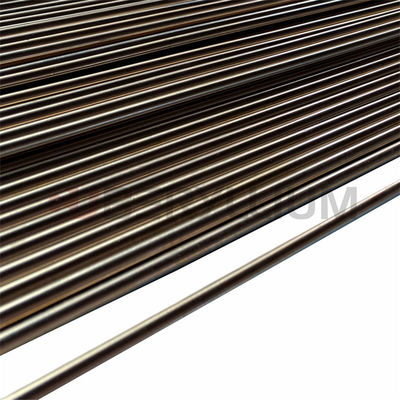

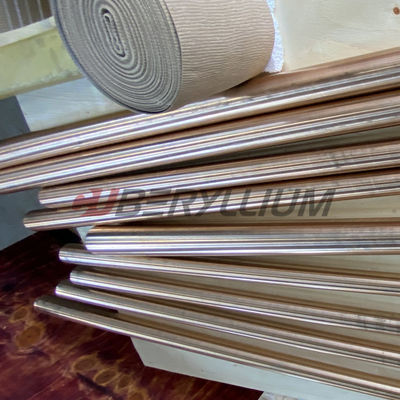

BECU C173 Copper Beryllium Round Rods CuBe2Pb CW102C Dia.1mm 2mm

| Place of Origin | China |

|---|---|

| Brand Name | CUBERYLLIUM® |

| Certification | ISO ROHS |

| Model Number | BECU C173 CuBe2Pb CW102C |

| Minimum Order Quantity | 30kg |

| Price | USD 30~50/KG |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Delivery Time | 10~15 Working days |

| Payment Terms | L/C, T/T |

| Supply Ability | 50T/Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | BECU C173 Rods | CUBERYLLIUM® Grade | CUBERYLLIUM®-173 |

|---|---|---|---|

| Standard | ASTM B196, QQ-C-530 | Surface | Bright, Polish |

| State | Hard/TD04 | Typical Application | Electrical And Industrial |

| Shape For Available | Rod&Bar | Brand | CUBERYLLIUM® |

| Highlight | Copper Beryllium Round Rods,BECU C173 Beryllium Round Rods,2mm Beryllium Round Rods |

||

BECU C173 CuBe2Pb CW102C Copper Beryllium Round Rods

| Product Type | Copper beryllium round rods |

| Material Grade | C173, CuBe2Pb, CW102C |

| Other Specification | Leaded beryllium copper alloy |

| Temper | H, TD04 |

| Standard | ASTM Standard |

| Product Size | 1mmx200mm, 2mmx2000mm |

About Cuberyllium:

Cuberyllium, has a team of highly qualified, motivated and experienced staff in production and sales to meet customers ever growing quality and service expectation.

We offer the best quality beryllium copper alloys which are used widely and are demanded all over the world.We are professional supplier in the industry engaged in manufacturing and exporting wide assortment of beryllium copper alloys in the market. These are available in different grades and dimensions and can be customized as per the clients' specification and requirement. We closely coordinate with our customers and design as per their specification.

Introduction of BeCu C173 CuBe2Pb CW102C Beryllium Copper Alloy:

The salient features of our C17300 Leaded Beryllium Copper Alloy are high tensile strength, technical precision, durability, low maintenance, etc. As the result, they are used for making switches, radiators, terminals, connectors, locks, keys, taps, general stamping, icons and statues, deep drawing articles, and many more.

| Item: | BeCu C173 CuBe2Pb CW102C Beryllium Copper Alloy |

| Features: | Finest raw materials used, high resistance to heat, C17300 rods are our advantages, and exported to Korea, Vietnam, Europe, India and so on. |

| Applications: | Electrical Industry, Electrical/ electronic connectors, Current-carrying springs, Precision screw machined parts, Welding electrodes, Bearings, Plastic molds. |

| Available Size: | Dia. 1mm, 2mm, 3mm, 5mm, 6mm ., Length 1m, 2m, 2.5m. Or Custom Dia. and Length. |

| Package : | Standard export seaworthy package , suit for all kind of transport or as required. |

Chemical Composition of BeCu C173 CuBe2Pb CW102C Beryllium Copper Alloy:

| Element | Content (%) |

| Be | 1.80-2.00% |

| Co+Ni(Min.) | 0.20 |

| Co+Ni+Fe (Max.) | 0.60 |

| Pb(Max.) | 0.2-0.6 |

| Others(Max.) | 0.05 |

| Cu | Rem. |

Typical Physical Properties of BeCu C173 CuBe2Pb CW102C Beryllium Copper Alloy:

| Properties | Metric |

| Density(g/cm3) | 8.36 |

| Density (during age hardening, 2% max. decrease in length and 6% max. increase in density)(g/cm3) | 8.25 |

| Elastic Modulus (kg/mm2 (103)) | 13.40 |

| Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C) | 17x10-6 |

| Melting Point | 870°C -980°C |

| Thermal Conductivity(cal/(cm-s-°C)) | 0.25 |

Beryllium Copper Photo:

![]()

RFQ:

- How can I identify high-quality copper alloy products?

By the physical shape, the proper analysis, and the correct mechanical values.

- Is there a possibility to order customized copper alloys?

Different copper alloys are tested for a very long time and always applicable to individual demands.

We have the experience to help customers producing customized products as per the customers' drawings.

- What is the delivery time of copper alloys from Cuberyllium?

Usually with 7-10 working days, it will depend on the final qty requested by customers.

- What are the disadvantages of using Copper Alloys?

Copper Alloys can be more susceptible to corrosion, particularly oxidation. which can impact it suitability for some applications.

- What are the benefits of using Copper Alloys?

Copper Alloys offer many manufacturing benefits including strength, conductivity, corrosion resistance, machinability and ductility. With superior electrical and thermal conductivity, and an attractive appearance, Copper Alloys are suitable for a wide range of applications.