-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

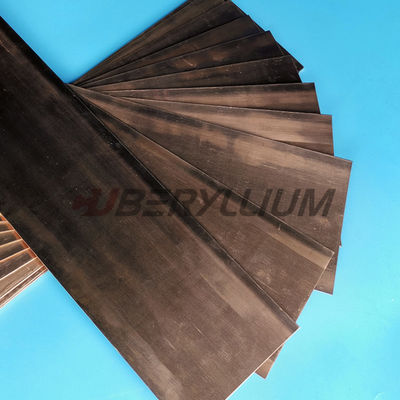

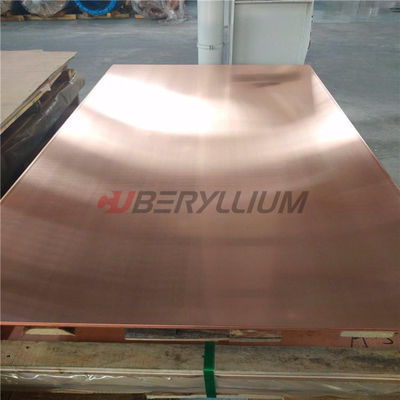

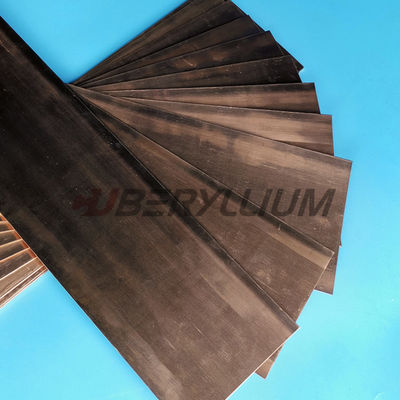

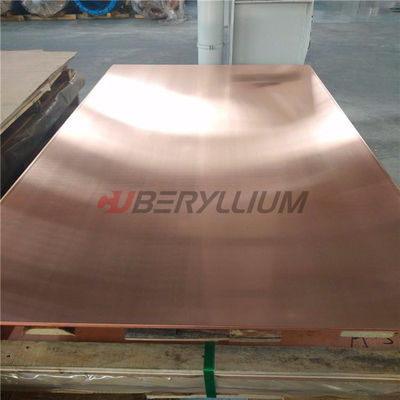

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

UNS C17510 Alloy 3 Nickel Beryllium Copper Sheet ASTM B535 140x45x1800mm

| Place of Origin | China |

|---|---|

| Brand Name | CUBERYLLIUM |

| Certification | ISO ROHS |

| Model Number | UNS.C17510 Alloy 3 |

| Minimum Order Quantity | 30kg |

| Price | USD 30~50/KG |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Delivery Time | 10~15 Working days |

| Payment Terms | L/C, T/T |

| Supply Ability | 50T/Month |

| Name | Nickel Beryllium Copper Sheet | Length | 140*45*1800mm |

|---|---|---|---|

| ASTM | ASTM B534 | Temper | TF00 |

| Surface | Bright | Heat Treatment | 3 Hr 315C-330C |

| Typical Application | Plastic Moulds | Application | Industry |

| Highlight | UNS C17510 Nickel Beryllium Copper,Alloy 3 Nickel Beryllium Copper,ASTM B535 Nickel Beryllium Copper |

||

UNS.C17510 Alloy 3 Nickel Beryllium Copper Sheet By ASTM B535 140*45*1800mm

Product Normal Description:

Product Name: Nickel beryllium copper sheet

Grade: UNS. C17510/ Alloy 3

Standard: ASTM B534

Plate Size: 140*45*1800mm

State: TF00

Typical Application: Industry

Product Brand: CUBERYLLIUM®

CUBERYLLIUM® manufactures copper beryllium in several distinct compositions. These fall into two categories: alloys selected for high strength (Alloys 172,173,170) and alloys selected for high conductivity (Alloys 751,750,741). And Gost standard QBe2,QBe1.9Ti for Russia Market. Also Supply Master alloy : CuBeryllium-200; CuBeryllium-275);CuBeryllium-350 and Cuberyllium-400 to global factory.

CUBERYLLIUM ®-751 also named -C17510 (CDA 751) Alloy 751 is a high conductivity copper beryllium alloy used in applications requiring a combination of high thermal conductivity with moderate strength. Alloy 751, supplied with certified mechanical properties, is fully heat treated and no additional treatment is required. Alloy 751 is nonmagnetic and provides excellent resistance to thermal fatigue.

Chemical Composition of UNS.C17510 Alloy 3 Nickel Beryllium Copper Alloy:

| CUBERYLLIUM® Brand | UNS-Number | Beryllium | Nickel | Fe | Si | Copper |

| Cuberyllium-C751 | C17510 | 0.20-0.60 | 1.4~2.2 | <0.1 | <0.2 | Balance |

Note: Copper plus additions equal 99.5% Minimum.

Typical Physical Properties of UNS.C17510 Alloy 3 Nickel Beryllium Copper Alloy:

| PRODUCT PROPERTY | US CUSTOMARY | METRIC |

| Coefficient of Thermal Expansion | 9.8 . 10-6 per oF (68-392 F) | 17.6 . 10 6 per C (20-200 C) |

| Density | 0.317 lb/in3 @ 68 F | 8.77 gm/cm3 @ 20 C |

| Electrical Conductivity | 48 %IACS @ 68 F | 0.281 MegaSiemens/cm @ 20 C |

| Electrical Conductivity | 45 %IACS @ 68 F | 0.263 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 22.8 ohms-cmil/ft @ 68 F | 3.79 microhm-cm @ 20 C |

| Melting Point Liquid US | 1955 F | 1068 C |

| Melting Point Solid US | 1885 F | 1029 C |

| Modulas of Elasticity in Tension | 19200 ksi | 132400 MPa |

| Modulas of Rigidity | 7500 ksi | 51710 MPa |

| Specific Gravity | 8.77 | 8.77 |

| Specific Heat Capacity | 0.1 Btu/lb/F @ 68 F | 419.0 J/kg . K at 293 K |

| Thermal Conductivity | 120.0 Btu . ft/(hr . ft2 . F) @ 68 F | 207.7 W/m . K at 20 C |

Typical Applications of UNS.C17510 Alloy 3 Nickel Beryllium Copper Alloy:

| • Bearings and bushes |

| • Plastic moulds |

| • Corrosion resistant components |

| • Current carrying springs |

| • Welding electrodes |

| • Electrical and electronic connectors |

Product Photo:

![]()

What are the Properties of Beryllium Copper?

Properties of BeCu:

Beryllium copper is a ductile, machinable, and weldable alloy.

BeCu has an excellent response to precipitation-hardening treatments.

BeCu has excellent thermal conductivity (62 Btu/ft-deg.F-H), and it is about 3-5 times more conducting than Tool steel.

It shows resistance to stress relaxation.

It is resistant to non-oxidizing acids such as hydrochloric acid (HCl) and carbonic acid (H2CO3), to plastic decomposition products, to abrasive wear, and galling.

It can be heat-treated for increased strength, durability, and electrical conductivity.

Beryllium copper displays the maximum strength (up to 1,400 MPa (200,000 psi)) of any copper-based alloy.