-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

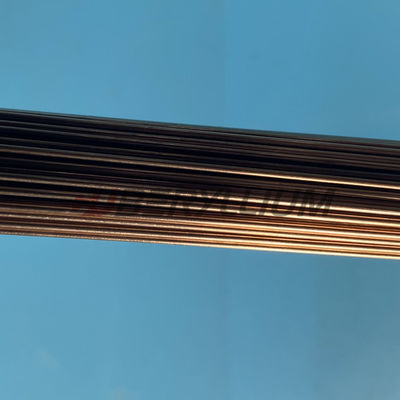

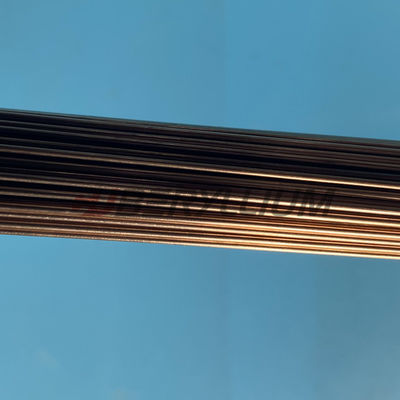

C17300 Solid Copper Rod TD04 Temper Bright Polish Surface

| Product Name | C17300 Solid Copper Rod | CUBERYLLIUM® Grade | CUBERYLLIUM®-173 |

|---|---|---|---|

| Standard | ASTM B196, QQ-C-530 | Surface | Bright, Polish |

| State | TD04 | Typical Application | Electrical And Industrial |

| Shape For Available | Rod&Bar | Brand | CUBERYLLIUM® |

| Density | 8.36g/cm3 | Length | Clients' Requirement |

| Specification | 2.0mmdia. X 2000mmL 1.3mmdia. X 2000mmL | ||

| Highlight | C17300 Solid Copper Rod,TD04 Temper Solid Copper Rod |

||

Material C17300 Solid Copper Rod TD04 Temper 2.0mmdia. x 2000mmL 1.3mmdia. x 2000mmL

Product Description:

Name: Solid copper rod

Grade: C17300

End Product Form: Rods/ Bars

Standard: ASTM B196, QQ-C-530

State of product: H(TD04)

Processing: Seamless / Welding

Feature: With high strength and high conductivity

Package: Pack in coil+waterproofing winding film+Drier+Wooden Case

Specification: 2.0mmdia. x 2000mmL 1.3mmdia. x 2000mmL

Chemical Composition of Material C17300 Copper Alloy:

| CUBERYLLIUM® Brand | UNS-Number | Beryllium | Cobalt + Nickel |

+Cobalt + Nickel + Iron |

Pb | Copper |

| Cuberyllium-C173 | C17300 | 1.80-2.00 | 0.20 min | 0.6 max | 0.2~0.6 | Balance |

Note: Copper plus additions equal 99.5% minimum.

Typical Physical Properties of Material C17300 Copper Alloy:

Density: 8.36g/cm3

Density before age hardening: 8.25g/cm3

Melting Range: 870~980℃

Elastic Modulus((kg/mm2 (103)): 13.4

Thermal Expansion Coefficient(20 °C to 200 °C m/m/°C): 17 x 10 -6

Thermal Conductivity(cal/(cm-s-°C)): 0.25

Mechanical and Electrical Properties of Material C17300 Copper Rod:

| Temper(*) | Diameter | Heat Treatment | Tensile Strength ksi |

Elogation Percent (Min) |

Electrical Conductivity Percent IACS |

Hardness Rockwell B or C Scale |

|---|---|---|---|---|---|---|

| A(TB00) | ALL SIZE | / | 400~600 | 30 | 15~19 | B45~85 |

H(TD04) |

5~10 | / | 660~900 | 5 | 15~19 | >B88 |

| >10~25 | / | 620~860 | 5 | 15~19 | ||

| >25 | / | 590~830 | 5 | 15~19 | ||

| AT(TF00) | ALL SIZE | 3 hr 320°C | 1100~1380 | 2 | 22~28 | C35~42 |

| HT(TH04) | 5~10 | 2 hr 320°C | 1200~1550 | 1 | 22~28 | C37~45 |

| >10~25 | 1150~1520 | 1 | 22~28 | C36~44 | ||

| >25 | 1120~1480 | 1 | 22~28 | C35~44 |

Applicable Specifications of Material C17300 Copper Alloy:

| Form | Specific Sub-Form | Applicaiton | System | Standard | Description |

|---|---|---|---|---|---|

| Bar | MILITARY | MIL-C-21657 | Copper-beryllium alloy, Low magnetic effect (for special purpose tools and equipment) | ||

| ASTM | B196/B196M |

Copper beryllium alloy rod and bar |

|||

| Rod | ASTM | B196/B196M | Copper beryllium alloy rod and bar | ||

| MILITARY | MIL-C-21657 | Copper-beryllium alloy, Low magnetic effect (for special purpose tools and equipment) | |||

| Wire | ASTM | B197/B197M | Copper beryllium alloy wire |

Product Photo:

![]()

What is Beryllium Copper?

Beryllium copper (BeCu), also known as copper beryllium (CuBe), beryllium bronze and spring copper, is a copper alloy with 0.5—3% beryllium and sometimes other elements. It has superb metalworking, framing and machining properties. It has many specialized applications in electrical industry, industrail and aviation.

The small proportion of beryllium to copper makes a group of high copper amalgams with quality as high as compound steel. The first of the two families, C17200 and C17300, incorporates high quality with moderate conductivity, while the subsequent family, C17500 and C17510, offers high conductivity with moderate quality.

Where is Beryllium Copper used?

Beryllium copper is a non-ferrous composite utilized in springs, spring wire, load cells, and different parts that must hold their shape under rehashed anxiety. It has high electrical conductivity and is utilized in low-flow contacts for batteries and electrical connectors.

Other Uses:

Ultra-low temperature cryogenic equipment, such as dilution refrigerators, because of its mechanical strength and relatively high thermal conductivity in this temperature range

Servicing magnetic resonance imaging (MRI) machines, where high strength magnetic fields make use of ferrous tools dangerous, and where magnetic materials in the field can disturb the image.

It has important applications in oilfield tools, aerospace landing gears, robotic welding, and mold making applications.