-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

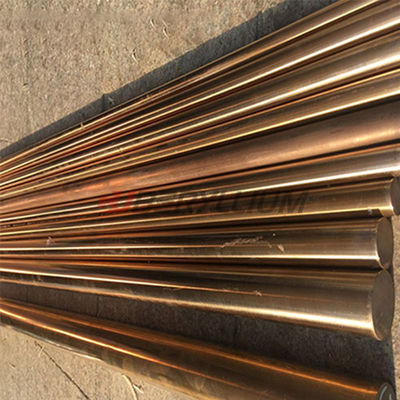

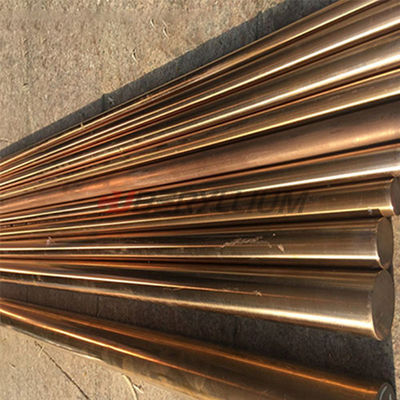

RWMA Class 4 C17200 Beryllium Bronze Rods Properties Ductility Weldability Machinability

| Place of Origin | China |

|---|---|

| Brand Name | CUBERYLLIUM® |

| Certification | ISO,SGS |

| Model Number | RWMA Class 4(C17200) |

| Minimum Order Quantity | 50 |

| Price | 30-50USD |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Delivery Time | 10~15days |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 200T/Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | RWMA Class 4(C17200) Beryllium Bronze Rods | CUBERYLLIUM® Grade | CUBERYLLIUM® 172 |

|---|---|---|---|

| Standard | ASTM B196,251,463; SAE J461,463; AMS 4533,4534,4535; AMS 4650,4651; RWMA Class 4 | Safe Handling | No Special Health Risk. |

| Machining Property | Good | Surface | Bright/Polished |

| Flatness | Good | State | A(TB00),1/2H (TD02), H(TD04),AT(TF00),HT(TH04) |

| Diameter | 5mm-100mm | Properties | Ductility, Weldability And Machinability |

| Elestic Modulus | 131Gpa | Melting Point(solidus) | 870℃ |

| Electrical Conductivity | 22-28% IACS | ||

| Highlight | RWMA Class 4 Beryllium Bronze Rods,C17200 Beryllium Bronze Rods,c17200 class 4 |

||

RWMA Class 4(C17200) Beryllium Bronze Rods With Ductility, Weldability And Machinability Properties

Product Normal Description:

Product Name: Beryllium bronze rods

Grade: RWMA Class 4(C17200)

Standard: ASTM B196,251,463; SAE J461,463; AMS 4533,4534,4535; AMS 4650,4651; RWMA Class 4

Product Diameter: 5mm-100mm

State: A(TB00),1/2H (TD02), H(TD04),AT(TF00),HT(TH04)

Typical Application: For electrical industry

Product Brand: CUBERYLLIUM®

Beryllium Bronze Alloy International Specification:

Rods/Bars/Tubes: ASTM B196,251,463; SAE J461,463; AMS 4533,4534,4535; AMS 4650,4651; RWMA Class 4

European Standards: CuBe2, Alloy 25, QBe2, BrB2, DIN.2.1247, CW101C to EN

Note:

ASTM: American Society for Testing and Materials

SAE: Society of Automotive Engineers

AMS: Aerospace Materials Specification(Published by SEA)

RWMA: Resistance Welder Manufacturers' Association

Note: Unless otherwise specified, material will be produced by ASTM.

C17200 Beryllium Bronze Performance:

- Beryllium bronze is a precipitation hardening alloy. After solution aging treatment, it has high strength, hardness, fatigue limit and elastic limit, small elastic hysteresis, and has corrosion resistance and processing properties.

- Wear resistance, low temperature resistance, non-magnetic, high conductivity, impact and no sparks.

- Strong electrical conductivity. It also has good fluidity and the ability to reproduce fine patterns.

- Beryllium copper alloy is an indispensable submarine cable repeater structure. Alternative materials.

Chemical Composition of Beryllium Bronze Alloy (CUBERYLLIUM ®-172):

| CUBERYLLIUM® Brand | UNS-Number | Beryllium | Cobalt + Nickel |

+Cobalt + Nickel + Iron |

Pb | Copper |

| Cuberyllium-C172 | C17200 | 1.80-2.00 | 0.20 min | 0.6 max | 0.02 Max | Balance |

Copper plus additions equal 99.5% Min.

Typical Physical Properties of Beryllium Bronze Alloy (CUBERYLLIUM ®-172):

| Density (g/cm3): | 8.36 |

| Density before age hardening (g/cm3): | 8.25 |

| Elastic Modulus (kg/mm2 (103)): | 13.4 |

| Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C): | 17 x 10-6 |

| Thermal Conductivity (cal/(cm-s-°C)): | 0.25 |

| Melting Range (°C): | 870-980 |

Mechanical and Electrical Properties of Beryllium Bronze Alloy Rods:

| Temper(*) | Diameter | Heat Treatment | Tensile Strength ksi |

Elogation Percent (Min) |

Electrical Conductivity Percent IACS |

Hardness Rockwell B or C Scale |

|---|---|---|---|---|---|---|

| A(TB00) | ALL SIZE | / | 400~600 | 30 | 15~19 | B45~85 |

| 1/2H(TB04) | 5~40 | / | 550~700 | 10 | 15~19 | >B78 |

H(TD04) |

5~10 | / | 660~900 | 5 | 15~19 | >B88 |

| >10~25 | / | 620~860 | 5 | 15~19 | ||

| >25 | / | 590~830 | 5 | 15~19 | ||

| AT(TF00) | ALL SIZE | 3 hr 320°C | 1100~1380 | 2 | 22~28 | C35~42 |

| HT(TH04) | 5~10 | 2 hr 320°C | 1200~1550 | 1 | 22~28 | C37~45 |

| >10~25 | 1150~1520 | 1 | 22~28 | C36~44 | ||

| >25 | 1120~1480 | 1 | 22~28 | C35~44 |

Product Photos:

![]()

Q1:Could you produce Beryllium Copper strip by Mill Hardened process.

A1:Yes, we could produce AM(TM00), 1/2HM(TM01).HM(TM04) XHM(TM06) XHMS(TM08).,we are the only factory could do harden strip in China.

Q2: What’s the advantages the Beryllium Copper of CUBERYLLIUM®.

A2: 1: The Biggest Coil weight could be reach 1200kg/Coil

2:We are the only one who melting by Vacuum semi-Continuous Furnace.

3:Surface further polishing for top clients.

Q3: Why you melting by Vacuum semi-Continuous Furnace.

A3:Could be get the Cast ingot without gas,smaller segregation, Grain Refinement

Q4: What's the payment terms?

A4: We accept T/T, L/C, Paypal etc. It can be negotiated when the amount is different.