-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

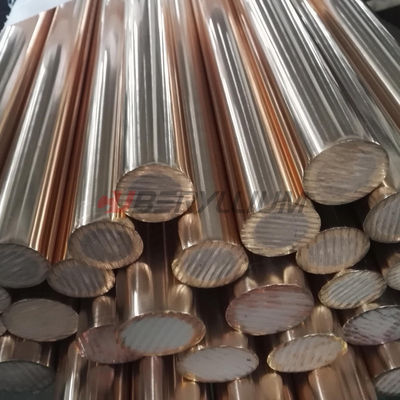

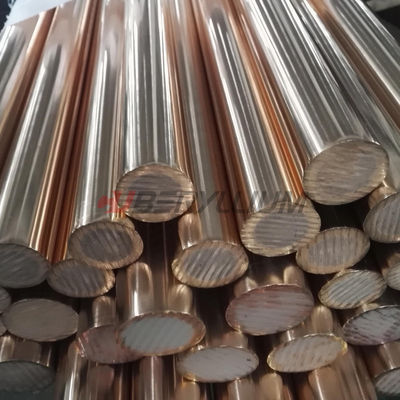

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

CDA 173 DIN2.1248 Copper Beryllium Alloys Rods For Electrical Industry

| Product Name | DIN2.1248 Copper Beryllium Bar | CUBERYLLIUM® Grade | CUBERYLLIUM®-173 |

|---|---|---|---|

| Standard | ASTM B196, QQ-C-530 | Surface | Bright, Polish |

| State | A(TB00), H(TD04), AT(TF00), HT(TH04) | Typical Application | Electrical And Industrial |

| Shape For Available | Rod&Bar | Brand | CUBERYLLIUM® |

| Density | 8.36g/cm3 | Length | Clients' Requirement |

| Size | According Customers' Requirement | ||

| Highlight | CDA 173 Copper Beryllium Alloys Rods,DIN2.1248 Copper Beryllium Alloys Rods,beryllium bronze alloy Rod |

||

Copper Beryllium Alloys Standard CDA 173 Copper Rods For Electrical Industry

CUBERYLLIUM® manufactures copper beryllium in several distinct compositions. These fall into two categories: alloys selected for high strength (Alloys 172,173,170) and alloys selected for high conductivity (Alloys 751,750,741). And Gost standard QBe2,QBe1.9Ti for Russia Market. Also Supply Master alloy : CuBeryllium-200; CuBeryllium-275);CuBeryllium-350 and Cuberyllium-400 to global factory.

| Product Name | Copper beryllium alloys/ copper rods |

|---|---|

| Product Grade | CDA 173 |

| Product Size | according customers' requirement |

| End Product Form | Rods/ Bars |

| Standards | ASTM B196, QQ-C-530 |

| State of Product | A(TB00),H(TD04),AT(TF00),HT(TH04) |

| Processing | Seamless / Welding |

| Feature | With high strength and high conductivity |

| Package | Pack in coil+waterproofing winding film+Drier+Wooden Case |

CUBERYLLIUM ®-173 also named -C17300 (CDA 173) offers the strength properties of C17300 with the added benefit of being “free machining”. C17300 rod and wire contain a small amount of lead to provide an alloy tailored for automatic machining operations. Lead promotes formation of finely divided chips thus extending cutting tool life.

Chemical Composition of Copper Beryllium Alloys Standard CDA 173 Copper Alloys:

| CUBERYLLIUM® Brand | UNS-Number | Beryllium | Cobalt + Nickel |

+Cobalt + Nickel + Iron |

Pb | Copper |

| Cuberyllium-C173 | C17300 | 1.80-2.00 | 0.20 min | 0.6 max | 0.2~0.6 | Balance |

Note: Copper plus additions equal 99.5% minimum.

Typical Physical Properties of Copper Beryllium Alloys Standard CDA 173 Copper Alloys:

Density: 8.36g/cm3

Density before age hardening: 8.25g/cm3

Melting Range: 870~980℃

Elastic Modulus((kg/mm2 (103)): 13.4

Thermal Expansion Coefficient(20 °C to 200 °C m/m/°C): 17 x 10 -6

Thermal Conductivity(cal/(cm-s-°C)): 0.25

Mechanical and Electrical Properties of Copper Beryllium Alloys Standard CDA 173 Copper Rods:

| Temper(*) | Diameter | Heat Treatment | Tensile Strength ksi |

Elogation Percent (Min) |

Electrical Conductivity Percent IACS |

Hardness Rockwell B or C Scale |

|---|---|---|---|---|---|---|

| A(TB00) | ALL SIZE | / | 400~600 | 30 | 15~19 | B45~85 |

H(TD04) |

5~10 | / | 660~900 | 5 | 15~19 | >B88 |

| >10~25 | / | 620~860 | 5 | 15~19 | ||

| >25 | / | 590~830 | 5 | 15~19 | ||

| AT(TF00) | ALL SIZE | 3 hr 320°C | 1100~1380 | 2 | 22~28 | C35~42 |

| HT(TH04) | 5~10 | 2 hr 320°C | 1200~1550 | 1 | 22~28 | C37~45 |

| >10~25 | 1150~1520 | 1 | 22~28 | C36~44 | ||

| >25 | 1120~1480 | 1 | 22~28 | C35~44 |

Product Photo:

![]()

Typical Applications for Copper Beryllium Alloys Standard CDA 173 Copper Alloys:

Electrical Industry: Switch Parts, Relay parts, RF Coaxial Connector, Contact Bridges, Electrical Connectors, Fuse Clips, Electrical Motor Components, Navigational Instruments, Electrical Switch and Relay Blades.

Industrial: Bushings, Welding Equipment, Non-Sparking Safety Tools, Shafts, Springs, Rolling Mill Parts, Spline Shafts, Pump Parts, Valves, Bourdon Tubes, Bellows, Electrochemical Springs, Flexible Metal Hos

Key Technology of Beryllium Copper(Heat treatment)

Age Hardening

Age hardening significantly enhances the material’s strength. This reaction is generally carried out at temperatures between 260°C and 540°C depending on alloy and desired characteristics. This cycle causes the dissolved beryllium to precipitate as a beryllium rich (gamma) phase in the matrix and at the grain boundaries. It is the formation of this precipitate which causes the large increase in material strength. The level of mechanical properties attained is determined by the temperature and time at temperature. It should be recognized that beryllium copper has no room temperature aging characteristics.