-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

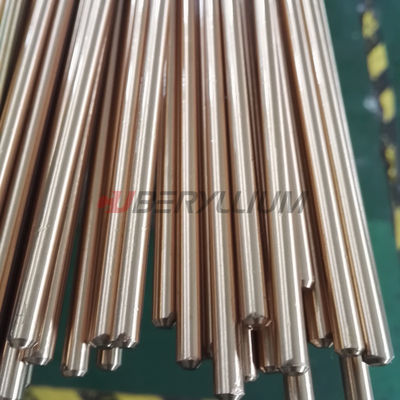

CW102C C17300 Beryllium Copper Rod 3x1000mm For Car Industry

| Product Name | CW102C (UNS.C17300) Beryllium Copper Alloys Rods | CUBERYLLIUM® Grade | CUBERYLLIUM®-173 |

|---|---|---|---|

| Standard | ASTM B196, QQ-C-530 | Surface | Bright, Polish |

| State | A(TB00), H(TD04), AT(TF00), HT(TH04) | Typical Application | Electrical And Industrial |

| Shape For Available | Rod&Bar | Brand | CUBERYLLIUM® |

| Density | 8.36g/cm3 | Length | Clients' Requirement |

| Size | 3*1000mm | ||

| Highlight | CW102C c17300 beryllium copper rod 3x1000mm,c17300 beryllium copper rod 3x1000mm,beryllium rods 3x1000mm |

||

CW102C (UNS.C17300) Beryllium Copper Alloys Rods 3*1000mm Used For Car Industry

Product Description:

Name: Beryllium copper alloys rods

Grade: CW102C (UNS.C17300)

Size: 3*1000mm, or according customers' requirement

End Product Form: Rods/ Bars

Standard: ASTM B196, QQ-C-530

State of product: A(TB00),H(TD04),AT(TF00),HT(TH04)

Processing: Seamless / Welding

Feature: With high strength and high conductivity

Package: Pack in coil+waterproofing winding film+Drier+Wooden Case

CUBERYLLIUM ®-173 also named -C17300 (CDA 173) offers the strength properties of C17300 with the added benefit of being “free machining”. C17300 rod and wire contain a small amount of lead to provide an alloy tailored for automatic machining operations. Lead promotes formation of finely divided chips thus extending cutting tool life.

Chemical Composition of CW102C (UNS.C17300) Beryllium Copper Alloys:

| CUBERYLLIUM® Brand | UNS-Number | Beryllium | Cobalt + Nickel |

+Cobalt + Nickel + Iron |

Pb | Copper |

| Cuberyllium-C173 | C17300 | 1.80-2.00 | 0.20 min | 0.6 max | 0.2~0.6 | Balance |

Note: Copper plus additions equal 99.5% minimum.

Typical Physical Properties of CW102C (UNS.C17300) Beryllium Copper Alloys:

Density: 8.36g/cm3

Density before age hardening: 8.25g/cm3

Melting Range: 870~980℃

Elastic Modulus((kg/mm2 (103)): 13.4

Thermal Expansion Coefficient(20 °C to 200 °C m/m/°C): 17 x 10 -6

Thermal Conductivity(cal/(cm-s-°C)): 0.25

Mechanical and Electrical Properties of CW102C (UNS.C17300) Beryllium Copper Alloys Rods:

| Temper(*) | Diameter | Heat Treatment | Tensile Strength ksi |

Elogation Percent (Min) |

Electrical Conductivity Percent IACS |

Hardness Rockwell B or C Scale |

|---|---|---|---|---|---|---|

| A(TB00) | ALL SIZE | / | 400~600 | 30 | 15~19 | B45~85 |

H(TD04) |

5~10 | / | 660~900 | 5 | 15~19 | >B88 |

| >10~25 | / | 620~860 | 5 | 15~19 | ||

| >25 | / | 590~830 | 5 | 15~19 | ||

| AT(TF00) | ALL SIZE | 3 hr 320°C | 1100~1380 | 2 | 22~28 | C35~42 |

| HT(TH04) | 5~10 | 2 hr 320°C | 1200~1550 | 1 | 22~28 | C37~45 |

| >10~25 | 1150~1520 | 1 | 22~28 | C36~44 | ||

| >25 | 1120~1480 | 1 | 22~28 | C35~44 |

Payment Terms & Delivery & After-sale Service

| Payment Terms |

|

|---|---|

| Delivery |

|

| After-sale Service | Nice after-sale service will be offered and it is a good tradition in our factory. |

Product Photo:

![]()

CW102C (UNS.C17300) Beryllium Copper Alloys International Specification:

Rods/Bars/Tubes: ASTM B196, QQ-C-530

Wires: ASTM B197, QQ-C-530

European Standards: CuBe2Pb, Alloy M25, UNS.C17300, DIN.2.1248, CW102C to EN

Note:

ASTM: American Society for Testing and Materials

SAE: Society of Automotive Engineers

AMS: Aerospace Materials Specification(Published by SEA)

RWMA: Resistance Welder Manufacturers' Association

Note: Unless otherwise specified, material will be produced by ASTM.