-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

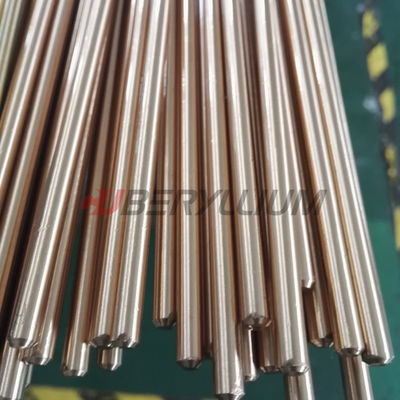

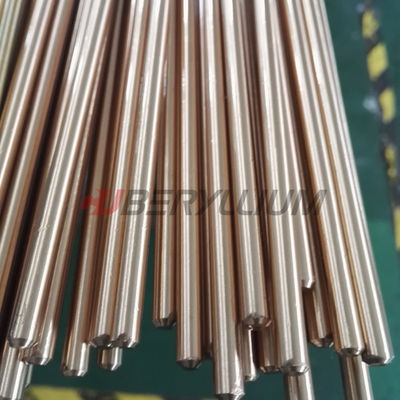

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

C17500 Beryllium Copper Round Bar 8x500mm For Resistance Welding Equipment

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Beryllium Copper C17500 Round Bar | ASTM | ASTM B441 |

|---|---|---|---|

| Surface | Bright | Specification | 8*500mm |

| State | AT(TF00) | Heat Treatment | 3 Hr 480℃ |

| Typical Application | Electrical Industry | Shape For Available | Rod&Bar |

| Hardness | B92~100 Rockwell B Scale | Brand | CUBERYLLIUM® |

| Tensile Strength | 680~900 Mpa | Elongation Percent | 10~30 Min |

| Electrical Conductivity | 45~60% IACS | ||

| Highlight | C17500 Beryllium Copper Round Bar 8x500mm,Beryllium Copper Round Bar 8x500mm,C17500 beryllium containing alloy |

||

Corrosion-Resistant Beryllium Copper C17500 Round Bar Size 8*500mm Used For Resistance Welding Equipment

Product Description:

Name: Beryllium Copper C17500 Round Bar

Grade: C17500

End Product Form: Rod/ Bar

Standard: ASTM B441

Processing: Seamless / Welding

Feature: Corrosion-resistant

Package: Pack in coil+waterproofing winding film+Drier+Wooden Case

Specification: 8*500mm

Introduction of Beryllium Copper C17500:

| Element | Alloy C17500 has a Chemical Formula of Becu. |

|---|---|

| Different Name of Beryllium Copper | Beryllium Bronze, Copper Beryllium (CuBe), Spring Copper |

| Feature | C17500 has moderate strength and its conductivity is around 50%. |

| Application | C17500 alloy is used in a wide variety of industrial processes in resistance welding equipment, switch parts, spring connectors, fasteners, fuse clips, die–casting plunger tips, springs, resistance and spot welding tips, connectors, seam welding dies, relay parts, tooling for plastic moulds, washers, etc. It is available in sheets, round tubes, rectangular bars, flat bars, round wires, coils, square bars, plates, round bars, hexagon bars and various custom made shapes. |

Chemical Composition of Beryllium Copper C17500 Alloys:

| CUBERYLLIUM® Brand | UNS-Number | Beryllium | Cobalt | Nickel | Cobalt+Nickel | Lead | Copper |

| Cuberyllium-C750 | C17500 | 0.40-0.70 | 2.4~2.7 | - | - | - | Balance |

Related material specifications of Beryllium Copper C17500 Alloys:

Rods/Bars/Tubes: ASTM B441, SAE J461, 463; RWMA Class 3

Strips: ASTM B534

Sheets: ASTM B534

Wires: ASTM B441

Plates: ASTM B534, SAE J461, RWMA Class 3

European Standards: CuCo2Be, CuCoBe, UNS. C17500, Alloy 10, DIN 2.1285, CW104C to EN

Note:

ASTM: American Society for Testing and Materials

SAE: Society of Automotive Engineers

AMS: Aerospace Materials Specification(Published by SEA)

RWMA: Resistance Welder Manufacturers' Association

Note: Unless otherwise specified, material will be produced by ASTM.

Typical Physical Properties of Beryllium Copper C17500 Alloys:

| Density | 8.83 | g/cm3 |

| Density before age hardening | 8.75 | g/cm3 |

| Melting Range | 1000~1070 | ℃ |

| Elastic Modulus | 14.1 | (kg/mm2 (103) |

| Thermal Expansion Coefficient | 18 x 10 -6 | 20 °C to 200 °C m/m/°C |

| Thermal Conductivity | 0.48 | cal/(cm-s-°C) |

Mechanical and Electrical Properties of Copper Beryllium Rod&Bar and Tube of CUBERYLLIUM®-750:

| Temper(*) | Diameter | Heat Treatment |

Tensile Strength Mpa |

Elongation Percent (Min) |

Electrical Conductivity Percent IACS |

Hardness Rockwell B Scale |

|---|---|---|---|---|---|---|

| A(TB00) | ALL SIZE | / | 240~380 | 20~40 | 20~35 | B20~50 |

|

H(TD04) |

ALL SIZE | / | 440~550 | 10~20 | 20~35 | B20~30 |

| AT(TF00) | ALL SIZE | 3 hr 480℃ | 680~900 | 10~30 | 45~60 | B92~100 |

| HT(TH04 | ALL SIZE | 2 hr 480 ℃ | 750~960 | 5~30 | 48~60 | B95~102 |

Product Photo:

![]()

Key Technology of Beryllium Copper(Heat treatment)

Age Hardening

Age hardening significantly enhances the material’s strength. This reaction is generally carried out at temperatures between 260°C and 540°C depending on alloy and desired characteristics. This cycle causes the dissolved beryllium to precipitate as a beryllium rich (gamma) phase in the matrix and at the grain boundaries. It is the formation of this precipitate which causes the large increase in material strength. The level of mechanical properties attained is determined by the temperature and time at temperature. It should be recognized that beryllium copper has no room temperature aging characteristics.

FAQ:

Q1:What’s the advantages the Beryllium Copper of CUBERYLLIUM®?

A1: 1: The Biggest Coil weight could be reach 1200kg/Coil

2:We are the only one who melting by Vacuum semi-Continuous Furnace.

3:Surface further polishing for top clients.

Q2: How about your payment terms?

A2: Generally, 30% as deposit by T/T, then 70% should be paid before the delivery.

Q3: Why you melting by Vacuum semi-Continuous Furnace?

A3:Could be get the Cast ingot without gas,smaller segregation, Grain Refinement

Q4: What's the payment terms?

A4: We accept T/T, L/C, Paypal etc. It can be negotiated when the amount is different.