-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

RWMA Class 3 Material CuCo2Be Beryllium Copper Rod Diameter 50mm

| Place of Origin | China |

|---|---|

| Brand Name | CUBERYLLIUM |

| Certification | ISO ROHS |

| Model Number | RWMA Class 3 Material CuCo2Be |

| Minimum Order Quantity | 30kg |

| Price | USD 30~50/KG |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Delivery Time | 10~15 Working days |

| Payment Terms | L/C, T/T |

| Supply Ability | 50T/Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | RWMA Class 3 Material CuCo2Be Beryllium Copper Rod | ASTM | ASTM B441 |

|---|---|---|---|

| Surface | Bright | Specification | 50mm Dia. |

| State | AT(TF00) | Heat Treatment | 3 Hr 480℃ |

| Typical Application | Electrical Industry | Shape For Available | Rod&Bar |

| Hardness | B92~100 Rockwell B Scale | Brand | CUBERYLLIUM® |

| Tensile Strength | 680~900 Mpa | Elongation Percent | 10~30 Min |

| Electrical Conductivity | 45~60% IACS | ||

| Highlight | Rod C17500 Beryllium Copper,CuCo2Be Beryllium Copper Rod,Beryllium Copper Rod Diameter 50mm |

||

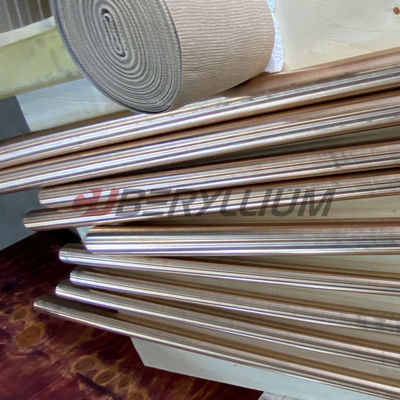

RWMA Class 3 Material CuCo2Be Beryllium Copper Rod Diameter 50mm Copper Rods

Product Description:

Name: Beryllium Copper Rod

Grade: RWMA Class 3 / CuCo2Be

End Product Form: Rod/ Bar

Standard: ASTM B441

Processing: Seamless / Welding

Feature: Anti corrosion and wear resistant materials

Package: Pack in coil+waterproofing winding film+Drier+Wooden Case

Specification: 50mm Dia.

About CUBERYLLIUM®:

Cuberyllium is one of the eminent manufacturer and exporter of high Grade Beryllium Copper Alloys, including beryllium copper strips, beryllium copper rods, beryllium copper bars, beryllium copper plates, beryllium copper sheet, beryllium copper wires, beryllium copper tubes and so no.

Cuberyllium offers a commendable range of beryllium copper alloys with competitive price. We offer beryllium copper alloys that are fabricated by our adroit professionals using supreme class raw material as per the set industry norms.

Chemical Composition of RWMA Class 3 Material CuCo2Be Beryllium Copper Alloy:

| C17500(CuCo2Be) | ||

| Cu/ Copper | Be/ Beryllium | Co |

| % rem | % 0.4-0.7 | % 2.4-2.7 |

Physical Properties of RWMA Class 3 Material CuCo2Be Beryllium Copper Alloy:

| Density | Density before age hardening | Specific Heat | Electrical Conductivity (I.A.C.S) | Thermal Conductivity |

| 8.83g/cm³ | 875.g/cm³ | 0.42 J/g.K | Min. 42% | 230 W/m.K |

Typical Applications for RWMA Class 3 Material CuCo2Be Beryllium Copper Alloy:

Resistance Welding Electrodes

Seam Weldings Wheels

Plunger Tips for Aluminum Die-Casting

Molds for Low Gravity Die-Casting

Circuit Breaker Switches

Electrical Components

Molds for Plastic Injection

Mechanical and RWMA Class 3 Material CuCo2Be Beryllium Copper Rod:

| Temper(*) | Diameter | Heat Treatment |

Tensile Strength Mpa |

Elongation Percent (Min) |

Electrical Conductivity Percent IACS |

Hardness Rockwell B Scale |

|---|---|---|---|---|---|---|

| A(TB00) | ALL SIZE | / | 240~380 | 20~40 | 20~35 | B20~50 |

|

H(TD04) |

ALL SIZE | / | 440~550 | 10~20 | 20~35 | B20~30 |

| AT(TF00) | ALL SIZE | 3 hr 480℃ | 680~900 | 10~30 | 45~60 | B92~100 |

| HT(TH04 | ALL SIZE | 2 hr 480 ℃ | 750~960 | 5~30 | 48~60 | B95~102 |

Product Photo:

![]()

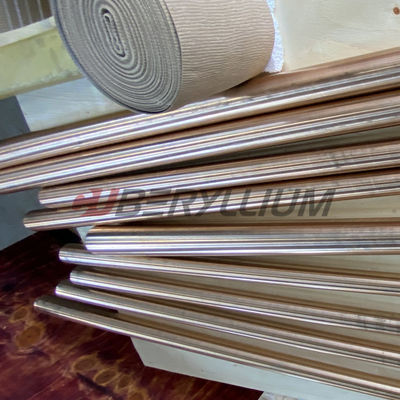

Beryllium Copper Bar Packaging & Shipping Policy

![]()

Beryllium Copper Bar packing will be according to international standard in bundles strapped by strips then into wooden case to avoid any damage.

Delivery: Usually within 10-25 days or asap if we have enough stock

Our Advantages:

Superior quality

Proactive customer service

Innovative solutions

Extremely fast turn around

Technical Support

Together we can achieve substantial amount of productivity for our applications, we can also develop and arrange mechanical properties according to specific requirements.