-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

Material Cuco2be CW104C Cobalt Copper Beryllium Wires UNS C17500 0.8mm 0.9mm 1mm

| Place of Origin | China |

|---|---|

| Brand Name | CUBERYLLIUM |

| Certification | ISO ROHS |

| Model Number | UNS C17500 (CW104C) |

| Minimum Order Quantity | 30kg |

| Price | USD 30KG |

| Packaging Details | Pack in coil+waterproofing winding film+Drier+Wooden Case |

| Delivery Time | 10~15 Working days |

| Payment Terms | L/C, T/T |

| Supply Ability | 50T/Month |

| Product Name | UNS C17500 (CW104C) Cobalt-Beryllium Copper Wires | CUBERYLLIUM® Grade | CUBERYLLIUM® 750 |

|---|---|---|---|

| Diameter Range | 0.08mm~6mm | ASTM | ASTM B441 |

| Temper | A(TB00), H(TD04), AT(TF00), HT(TH04) | Surface | Bright |

| Package | On Spools And In Coils | Typical Application | Electronic Connectors |

| Shape For Available | Rod Or Coil Wire | Hot Working | Have Good Hot Working Property |

| Cold Working | Have Excellent Cold Working Property | ||

| Highlight | material cw104c,cuco2be cw104c 0.8mm 0.9mm,C17500 becu beryllium copper 0.8mm 0.9mm |

||

UNS C17500 (CW104C) Cobalt-Beryllium Copper Wires Thickness 0.8mm, 0.9mm, 1mm

Product Description:

Name: Cobalt-beryllium copper wires

Grade: UNS C17500 (CW104C)

Specification: Thickness 0.8mm, 0.9mm, 1mm

Surface: Bright

State: A(TB00), H(TD04), AT(TF00), HT(TH04)

Features: High conductivity

Application: For Electronic connectors

CUBERYLLIUM® manufactures copper beryllium in several distinct compositions. These fall into two categories: alloys selected for high strength (Alloys 172,173,170) and alloys selected for high conductivity (Alloys 751,750,741). And Gost standard QBe2,QBe1.9Ti for Russia Market. Also Supply Master alloy : CuBeryllium-200; CuBeryllium-275);CuBeryllium-350 and Cuberyllium-400 to global factory.

Introduction of Material UNS C17500 Copper Alloy:

CUBERYLLIUM ®-750 also named -C17500 (CDA 750).

|

Material Properties |

Hard copper alloy with high thermal conductivity amd high mechanical properties combined with good hardness and high temperature strength. |

|---|---|

| Application Area | Spot welding electrodes and seam welding discs for stainless steel, monel and nickel alloys, flash welding dies, wire mesh electrodes, plastic blow and injection moulds and inserts in steel tools for higher cooling rates, nozzles and needles for hot runner systems, plunger tips in aluminum die casting machines, moulds for non-ferrous metal castings (as copper, brass, bronze), welding tools in plastic packaging. |

| Heat Treatment | Delivered in heat treated conditions. |

Chemical Composition of UNS C17500 (CW104C) Cobalt-Beryllium Copper Alloy:

| CUBERYLLIUM® Brand | UNS-Number | Beryllium | Cobalt | Fe | Si | Copper |

| Cuberyllium-C750 | C17500 | 0.40-0.70 | 2.4~2.7 | <0.1 | <0.2 | Balance |

Note: Copper plus additions equal 99.5% Min.

Typical Physical Properties of UNS C17500 (CW104C) Cobalt-Beryllium Copper Alloy:

| Density | 8.83 | g/cm3 |

| Density before age hardening | 8.75 | g/cm3 |

| Melting Range | 1000~1070 | ℃ |

| Elastic Modulus | 14.1 | (kg/mm2 (103) |

| Thermal Expansion Coefficient | 18 x 10 -6 | 20 °C to 200 °C m/m/°C |

| Thermal Conductivity | 0.48 | cal/(cm-s-°C) |

Mechanical and Electrical Properties of UNS C17500 (CW104C) Cobalt-Beryllium Copper Wires:

| Temper(*) | Heat Treatment |

Tensile Strength Mpa |

Elongation Percent (Min) |

Electrical Conductivity Percent IACS |

|---|---|---|---|---|

| A(TB00) | / | 240~380 | 20~60 | 20~30 |

| H(TD04) | / | 440~550 | 2~20 | 20~30 |

| AT(TF00) | 3 hr 490℃ | 690~900 | >10 | 45~60 |

| HT(TH04 | 2 hr 490 ℃ | 750~960 | >10 | 48~60 |

Related Material Specifications of UNS C17500 (CW104C) Cobalt-Beryllium Copper Alloy:

Wires: ASTM B441

Rods/Bars/Tubes: ASTM B441, SAE J461, 463; RWMA Class 3

Strips: ASTM B534

Sheets: ASTM B534

Plates: ASTM B534, SAE J461, RWMA Class 3

European Standards: CuCo2Be, CuCoBe, UNS. C17500, Alloy 10, DIN 2.1285, CW104C to EN

Note:

ASTM: American Society for Testing and Materials

SAE: Society of Automotive Engineers

AMS: Aerospace Materials Specification(Published by SEA)

RWMA: Resistance Welder Manufacturers' Association

Note: Unless otherwise specified, material will be produced by ASTM.

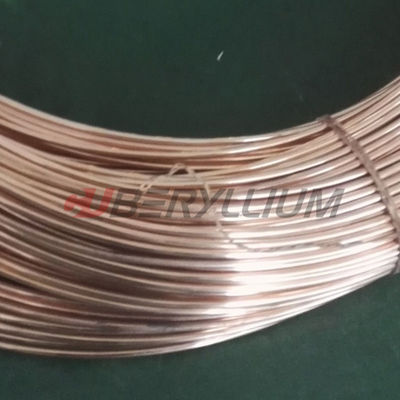

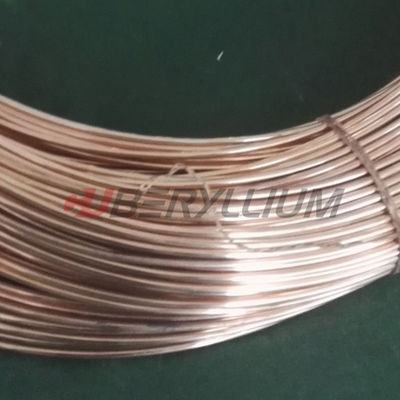

Product Photo:

![]()

FAQ:

Q1:Could you produce Beryllium Copper strip by Mill Hardened process.

A1:Yes, we could produce AM(TM00), 1/2HM(TM01).HM(TM04) XHM(TM06) XHMS(TM08).,we are the only factory could do harden strip in China.

Q2: What’s the advantages the Beryllium Copper of CUBERYLLIUM®.

A2: 1: The Biggest Coil weight could be reach 1200kg/Coil

2:We are the only one who melting by Vacuum semi-Continuous Furnace.

3:Surface further polishing for top clients.

Q3: Why you melting by Vacuum semi-Continuous Furnace.

A3:Could be get the Cast ingot without gas,smaller segregation, Grain Refinement

Q4: What's the payment terms?

A4: We accept T/T, L/C, Paypal etc. It can be negotiated when the amount is different.