-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

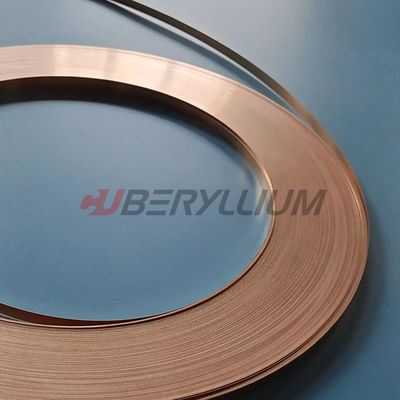

Beryllium Copper C17200 Industrial Strips 1/2H With Standard Tolerance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Beryllium Copper C17200 Industrial Strips | Max Coil Wt. | 2T |

|---|---|---|---|

| Thinnest Thick. | 0.254mm | Width | 27.5mm |

| Standard | ASTM B194, SAE J463, J461 | Safe Handling | No Special Health Risk. |

| Machining Property | Good | Surface | Bright/Polished |

| Flatness | Good | Temper | 1/2H |

| Coil Weight | Material Can Be Coiled In Apporximately 12kg Coils. | ||

| High Light | Industrial Strips C17200 Beryllium Copper,1/2H Temper Beryllium Copper Strip,C17200 Industrial Strips |

||

Beryllium Copper C17200 Industrial Strips 0.254mm x 27.5mm 1/2H With Standard Tolerance

Product Normal Description:

| Product Name | Beryllium copper industrial strips |

| Grade | C17200 |

| End Product Form | Strips/Tape |

| Standard | ASTM B194 |

| State of product | Half Hard(TD02) |

| Specification |

Thickness: 0.254mm Width: 27.5mm |

| Application | Industrial |

Introduction of Beryllium Copper C17200 Alloy:

Beryllium copper UNS.C17200 is also known as various names like spring copper, beryllium bronze, and copper beryllium.

Beryllium copper combines non-magnetic as well as non-sparking properties.

It has unique machining and metalworking qualities.

Beryllium copper is applicable in numerous applications because of its unique features

It is a flexible, weldable, and machinable alloy which resistant to non-oxidizing acids, plastic decomposition products, abrasive wear and galling.

It can handle high-temperature heat to improve its strength, durability, and electrical conductivity.

These properties allow it to fit in the various criteria of essential applications.

Chemical Composition of Beryllium Copper C17200 Copper Alloy:

| Numbering | Be | Co+Ni | Cu | Fe | Pb | Si | Al |

| C17200 | 1.8-2.0 | ≥0.2 | Margin | 0.15 | - | 0.15 | 0.15 |

Standard Specificaiton For Beryllium Copper C17200 Strips:

| Standards | ASTM B194 |

| Grade | Alloy 25 (C17200), CDA 172 |

| Specifications | AMS 4530, AMS 4533, AMS 4534, AMS 4650, AMS 4651, SAE J461, SAE J463, JIS H 3130, RWMA Class 4 |

| Temper | TB00, TD01-04, TF00, TH01-04, TM00-08 |

Temper Designations of Beryllium Copper C17200 Copper Strips:

| Cuberyllium Designation | ASTM | Mechanical and Electrical Properties of Beryllium Copper C17200 Copper Strips | ||||||

| Designation | Description | Tensile Strength (Mpa) |

Yield Strength 0.2% offset | Elongation Percent | HARDNESS (HV) |

HARDNESS Rockwell B or C Scale |

Electrical Conductivity (% IACS) |

|

| A | TB00 | Solution Annealed | 410~530 | 190~380 | 35~60 | <130 | 45~78HRB | 15~19 |

| 1/2 H | TD02 | Half Hard | 580~690 | 510~660 | 12~30 | 180~220 | 88~96HRB | 15~19 |

| H | TD04 | Hard | 680~830 | 620~800 | 2~18 | 220~240 | 96~102HRB | 15~19 |

| HM | TM04 | Mill hardened |

930~1040 | 750~940 | 9~20 | 270~325 | 28~35HRC | 17~28 |

| SHM | TM05 | 1030~1110 | 860~970 | 9~18 | 295~350 | 31~37HRC | 17~28 | |

| XHM | TM06 | 1060~1210 | 930~1180 | 4~15 | 300~360 | 32~38HRC | 17~28 | |

Product Photo of Beryllium Copper C17200 Copper Strips:

![]()

Beryllium Copper C17200 Strips Application:

Beryllium Copper C17200 Strips are known to deliver exceptional performance and are generally developed for meeting the demands.

C172 Beryllium Copper Strips uses in Power Plants

Beryllium Copper UNS C17200 Strips uses in Modern Architecture

C17200 Beryllium Copper Strips uses in Petroleum Industry

CDA 172 CuBe2 Strip uses in General Purpose Applications

Beryllium Copper Strip C17200 uses in Fabrication Industry

Copper Beryllium Alloy C17200 Strip uses in Oil & Gas Industry

Beryllium Copper CDA 172 Strip uses in Fertilizers

ASME SB194 Beryllium Alloy 25 Strip uses in Electronics

Beryllium Copper C172 Strip uses in Construction

Copper Beryllium C17200 Strips uses in Chemical Industries

Copper-Beryllium Alloy C17200 Strips uses in Plumbing