-

Beryllium Copper Alloy

-

C17200 Beryllium Copper

-

C17300 Beryllium Copper

-

C17510 Beryllium Copper

-

C17500 Beryllium Copper

-

Chromium Zirconium Copper

-

Dispersion Strengthened Copper

-

Beryllium Copper Wire

-

Beryllium Copper Sheet

-

Beryllium Copper Rods

-

Beryllium Copper Strip

-

Beryllium Copper Tube

-

Tellurium Copper Alloy

CuCo1Ni1Be Beryllium Copper Rods CW103C Cobalt Nickel Beryllium Copper Round Bar

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Shape | Round Rod, Round Bar | Material | CUCO1NI1BE |

|---|---|---|---|

| Brand | Cuberyllium | Composition | Cobalt, Nickel, Beryllium And Copper |

| Product Code | C17200 Beryllium Copper | Standard | ASTM B441 |

| Density | 8.83 | Temper | A(TB00),H(TD04),AT(TF00),HT(TH04) |

| High Light | CW103C Beryllium Copper Rod,Cobalt Nickel Beryllium Copper Rod,CuCo1Ni1Be Beryllium Copper Round Bar |

||

CUCO1NI1BE BERYLLIUM COPPER ROD-CW103C Cobalt Nickel Beryllium Copper Rod

Product Details:

| Product Material | CuCo1Ni1Be |

| End Product | Round rod, bar |

| Europe Standard | CW103C, DIN 2.1285 |

| Chemical Composition |

Be:0.40-0.70%, Co: 0.80-1.30%, Ni: 0.80-1.30%, Cu: Balance Note: Copper plus additions equal 99.5% minimum |

| State for rod | A(TB00),H(TD04),AT(TF00),HT(TH04) |

| Other available products | plates, flat bar |

| State for plate | AT(TF00),HT(TH04) |

Introduction of CUCO1NI1BE material:

CuCo1Ni1Be-CW103C(DIN.2.1285), Cobalt Nickel Beryllium Copper, contains low Cobalt, Nickel and Beryllium.

After hot forging and heat treatment process, the hardness, electrical conductivity and electrical conductivity of this material are also significantly improved.

By changing the heat treatment conditions, different electrical conductivity and mechanical combinations can be obtained;

CuCo1Ni1Be still has good strength and mechanical properties, and the electrical conductivity is between In the range of 45-60% copper, the ultimate tensile and mechanical properties are close to 140 ksi and RB 100, respectively, and all of its properties are comparable to CuCo2Be-C17500 and CuNi2Be-C17510, respectively.

Typical Physical Properties of CUCO1NI1BE material:

| Density(g/cm3) | 8.83 |

| Density before age hardening (g/cm3) | 8.75 |

| Modulus of elasticity (kg/mm2 (103)) | 14.1 |

| Coefficient of thermal expansion (20 °C to 200 °C m/m/°C) | 17 x 10-6 |

| Thermal conductivity | 209 W/m • at 20 C |

| Normal Melting range (°C) | 1000-1070 |

Note:

1). the units are based upon Metric.

2). the typical physical properties apply to age hardened products.

Our Normal Material Grades and Available End Products:

| C17200 | round rod, bar, plate, wire, strip, ribbon, foil, tube, blok |

| C17300 | round rod, bar |

| C17510 | round rod, bar, flat bar, plate |

| C17500 | round rod, bar, plate |

| CuCo1Ni1Be | round rod, bar, flat bar, palte |

Typical Use of CUCO1NI1BE material:

| Electrical Industry | |

| Fuse clips | switch components |

| relay components | connector non-ferrous metal materials |

| plastic mold tools | butt welding pliers |

|

submerged arc welding contacts |

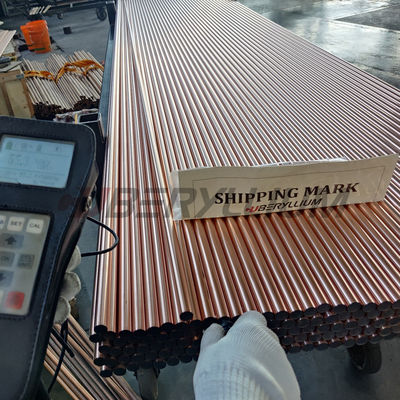

Product Photos:

![]()

![]()

RFQ:

- What is the delivery time of copper alloys from Cuberyllium?

Usually with 7-10 working days, it will depend on the final qty requested by customers. - What are the benefits of using Copper Alloys?

Copper Alloys offer many manufacturing benefits including strength, conductivity, corrosion resistance, machinability and ductility. With superior electrical and thermal conductivity, and an attractive appearance, Copper Alloys are suitable for a wide range of applications. - What are the disadvantages of using Copper Alloys?

Copper Alloys can be more susceptible to corrosion, particularly oxidation. which can impact it suitability for some applications. - Is there a possibility to order customized copper alloys?

Different copper alloys are tested for a very long time and always applicable to individual demands.

We have the experience to help customers producing customized products as per the customers' drawings.